Positive Displacement Pump

Positive displacement pumps are a type of vacuum pump that operates by trapping a fixed amount of pumping medium and then forcing it into a discharge pipe. These pumps are known for their ability to provide a constant flow rate regardless of changes in pressure or viscosity. They are commonly used in a variety of industries, including oil and gas, chemical processing, medical, food, metallurgy, energy and wastewater treatment etc. industries. One of the key advantages of positive displacement vacuum pump is their efficiency. Unlike centrifugal pumps, which rely on kinetic energy to move fluids, positive displacement pumps use mechanical action to transfer the medium, resulting in higher efficiency levels. This makes them an ideal choice for applications where precise control of flow rates is required. Whether it’s transferring gas, filling containers, or injecting chemicals, positive displacement vacuum pumps offer reliable and consistent performance.

Related Products

The positive displacement vacuum pump is a widely used type of vacuum pump, with several common variations. Among these, the screw vacuum pump, roots vacuum pump, and liquid ring vacuum pump are the most commonly employed. The screw vacuum pump operates by using two intermeshing screws to create a vacuum within the system. This design allows for efficient pumping of both liquid and gas. The roots vacuum pump, on the other hand, utilizes two rotating lobes that trap and transport gas molecules, effectively creating a vacuum. Lastly, the liquid ring vacuum pump employs a ring of liquid that creates a seal and generates the necessary suction for pumping. These three types of pumps offer varying advantages and are chosen based on specific application requirements.

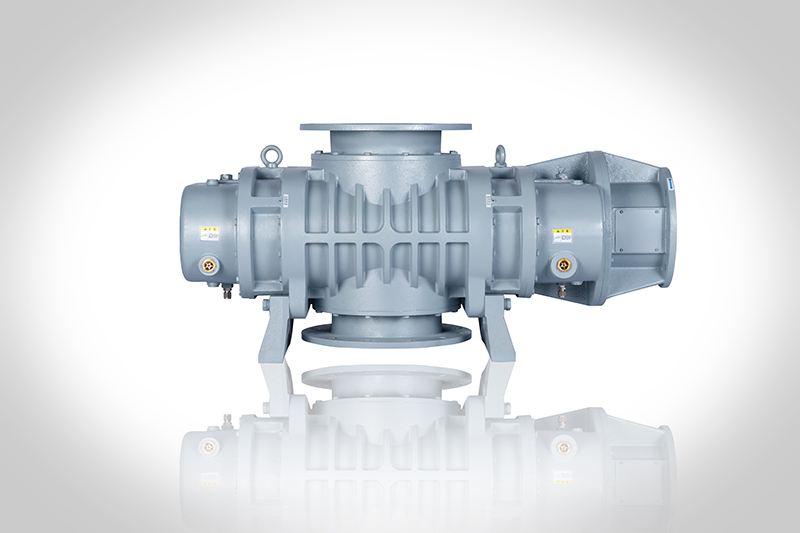

Roots Booster Pump

Five-point bearing design, double oil tank, nitrogen gas barrier, suitable for high temperature/high differential pressure/high vacuum condition, internal coating protection against corrosion, optional single-point mechanical seal or five-point mechanical seal, labyrinth seal.

Liquid Ring Vacuum Pump

Liquid ring vacuum pump’s rotor is installed eccentrically in the pump, and its rotation forces the working fluid to form an equal-thickness rotating liquid ring along the inner wall of the pump, the liquid ring and the rotor impeller together form a variable volume positive displacement vacuum pump.

Features

As one of the leading vacuum positive displacement pump manufacturers in China, Vacculex products have as follow features:

Dry Screw Vacuum Pump

- Variable pitch, high ultimate pressure, large pumping capacity and fast exhaust.

- Energy-saving design, 30% reduction in power consumption.

- Special profile design, few medium gas condensation.

- Spiral jacket cooling, low exhaust temperature, no carbonization, prevents jamming, long service life.

- Internal no oil or water, no waste oil wastewater treatment, facilitating solvent recovery.

- Configurable gas seal, inlet purging, steam cleaning, solvent cleaning.

- Corrosion-resistant coating treatment for fluid contact parts, strong anti-corrosion ability.

Roots Vacuum Pump

- One-piece double impeller, impeller and shaft are cast in one piece. The rotor has internal straight-through cavity with optional sealing plate design.

- Five point bearings design, high reliability.

- Special seal structure, the surface of the shaft in contact with the seal is polished to improve operating life and achieve zero leakage, eliminating cross contamination of oil and process gas.

- Synchronous gear is helical gear design, and installed at the drive end to reduce the distortion and deformation of the impeller, to improve the silence, stability and reliability.

- Double oil tank design can achieve sufficient lubrication, improve stability, optional cooling methods: air cooling, water cooling.

Liquid Ring Vacuum Pump

- No metal surfaces inside the pump that rub against each other, and the working fluid absorbs most of the compression temperature rise, making it suitable for conveying gases that are flammable, explosive or easily decomposed when exposed to temperature rise.

- Different working fluids can be used so that the conveyed gases are not contaminated.

- Can convey gases containing steam, moisture or solid particles.

- Simple structure, no need for suction and exhaust valves, smooth and reliable work, and uniform gas volume.

Advantage

- Consistent flow rate: Positive displacement pumps provide a constant flow rate, which is important in industries where a steady and reliable flow ofpumping mediumis required.

- High pressure capabilities: Positive displacement pumps are capable of generating high pressures, making them suitable for applications that require pumping fluids against significant resistance or through long pipelines.

- Handling viscous fluids: Positive displacement pumps are well-suited for handling viscous fluids, such as oils, sludge, or thick liquids. They can effectively move these substances without experiencing a significant loss in performance.

- Self-priming ability: Many positive displacement pumps are self-priming, meaning they can start pumping without the need for manual priming or assistance.

- Versatility: Positive displacement pumps can handle a wide range of mediumand materials, including abrasive and corrosive substances. This makes them versatile and applicable to various industries and processes.

Vacculex has established itself as a renowned industry leader in China’s vacuum pump market. With a specialization in the production of positive displacement pumps, we offer a comprehensive range of products to cater to diverse industrial applications. Our product lineup includes screw vacuum pumps, roots vacuum pumps, and customized vacuum systems tailored to meet specific requirements. At Vacculex, we are committed to delivering exceptional quality and performance. That’s why our vacuum pumps are manufactured using only the highest quality materials, ensuring optimal efficiency and safety. Whether you operate in the pharmaceutical, petrochemical, chemical industry, or any other field requiring vapor recovery, our extensive catalog of vacuum pumps provides a diverse range of options to suit your needs. Trust Vacculex for reliable and top-notch vacuum pump solutions that deliver unmatched performance and value.

Click for the Catalog →

Industry / Markets

Positive displacement pump is mainly used in pharmaceutical, chemical, petrochemical, metallurgy and other industries. With a wide range of vacuum pump options, we offer flexibility and efficiency for various industrial applications.

Evaporation/Crystallization

Distillation

Solvent recovery

Freeze Drying

Sterilization

Degassing

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

PBAT

PGA

ABS

PS

PC

Degassing

Stay In Touch

Do You Want To Know More About Positive Displacement Vacuum Pump

Contact Us For All Your Questions