PBAT:

PBAT is a kind of petrochemical-based biodegradable plastic. Because of its lower petroleum-based cost, PBAT need less investment and is expected to be the largest degradable plastic category in the future. PBAT is mainly made from adipic acid (AA), p-phthalic acid (PTA) and butanediol (BDO) as monomers, and is synthesized into Poly (butyleneadipate-co-terephthalate) by esterification or ester exchange reaction and polycondensation reaction in certain ratio. The final product is produced in three steps: esterification, polycondensation and pelletizing. Vacculex screw vacuum pumps are used in the three steps of pre-polycondensation, final polycondensation and material tackifying to provide a stable vacuum environment for the production, allowing PBAT esterification to reduce the reaction temperature to reduce the occurrence of BDO side reactions, reduce the generation of THF, and reduce raw material consumption and energy consumption.

Related Products

PGA:

Polyglycolic acid PGA is a fully biodegradable material with mild degradation conditions and can achieve rapid degradation in the natural environment under the action of water and microorganisms, with the final degradation products being carbon dioxide and water. the main characteristics of PGA are: good biocompatibility, high mechanical strength and high barrier properties. Large-scale production of PGAs is usually most common with the dimethyl oxalate (DMO) process route, which requires a vacuum environment for the polymerization reaction. Vacculex screw vacuum pumps and roots-screw vacuum units are used in product towers, roots-screw vacuum units are used in densification towers and roots-liquid ring vacuum units are used in de-volatilization equipment, which have advantages of large pumping speed, large compression ratio and low noise, providing strong technical support for efficient production.

Related Products

ABS:

ABS material is graft copolymer of acrylonitrile, 1,3-butadiene, styrene three monomers, also known as ABS resin, its largest application areas are automotive, electronic appliances, building materials, instruments and machinery and other multi-industry fields. Its production process is more used in the emulsion grafting of the body SAN blending, the process DV kettle need to use vacuum devices, some components in the suction medium are flammable and explosive, and have special odor, toxicity, strong corrosiveness and easy to solidify and other characteristics, so the unit requirements are higher: 1. explosion-proof; 2. anti-corrosion; 3. zero leakage; 4. temperature control.

Related Products

Polystyrene (PS):

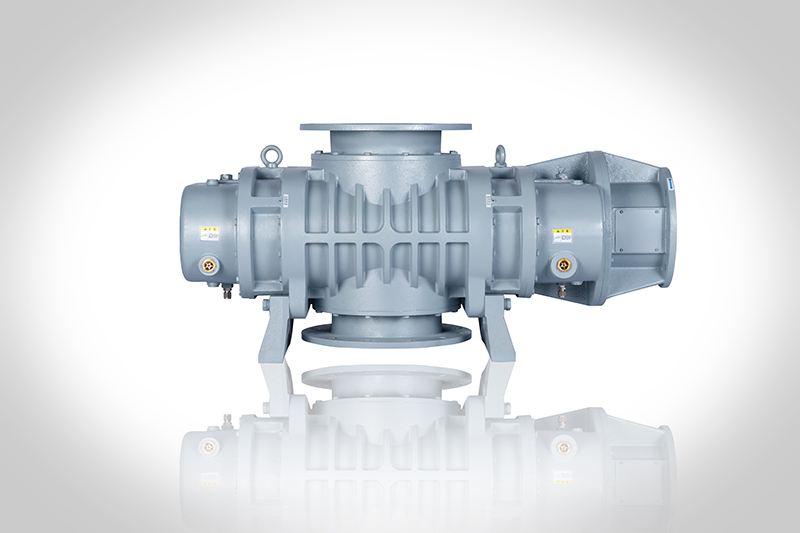

Polystyrene (PS) is a polymer synthesized by free radical polymerization of styrene monomer, which is a colorless and transparent thermoplastic. The suction medium is flammable and explosive, so the requirements for the vacuum device are higher: 1. Explosion-proof; 2. Zero leakage. Vacculex Roots vacuum pump (mechanical booster pump) can adopt direct connection or pulley transmission to correspond to different pumping speed requirements of customers; it adopts five-point mechanical seal to ensure clean and oil-free pump chamber and zero leakage of flammable and explosive, toxic and harmful gases; the mechanical seal is equipped with Karz O-ring inside to ensure safe sealing and corrosion resistance, etc. For system energy saving and pressure stabilization, frequency conversion control is adopted.

Related Products

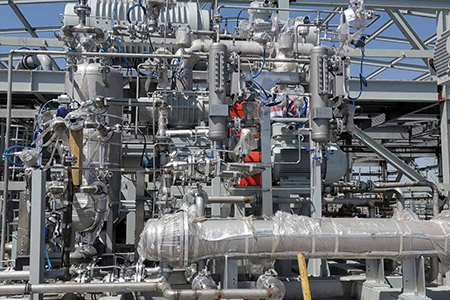

Polycarbonate (PC):

As a high-end petrochemical product, polycarbonate is the thermoplastic material with the fastest growing demand among the five major engineering plastics. It has excellent comprehensive properties and is widely used in electronic appliances, sheet containers, automotive industry, medical equipment, protective equipment and other fields. It has rapidly expanded to emerging fields such as aerospace, optical components, and optoelectronic information. In its production process, phenol recovery tower, DMC recovery tower, DPC recovery tower, thin film evaporator and DPC purification tower all need vacuum devices.

Related Products

Degassing:

Degassing of plastics reduces odors and improves the reliability and transparency of products. For example: degassing of the plastic melt during extrusion, where the trapped gas and water are extracted directly in the extruder screw area. This degassing process can significantly improve the physical properties and structure of the final product. Another example: equipment for the production of rubber parts requires vacuum to evacuate air from the die casting mold to prevent air bubbles and accelerate rubber aggregation. WEGUELE dry vacuum pumps and liquid ring pumps are commonly used for this application.

Related Products

Would like to start a communication with us?

Any questions, please contact our team, we will get back to you soon.