Evaporation/Crystallization:

Using vacuum to reduce the crystallization temperature by decompression and increase the volatilization of solvent under low pressure conditions, vacuum crystallization is actually using vacuum cooling technology to combine cooling crystallization and evaporation crystallization to achieve crystallization more efficient, lower energy consumption and more hygienic, which can effectively solve the problem of higher boiling point of solvent or lower crystallization temperature. Typical applications of Vacculex vacuum pumps can be referred to the use in the field of thin film evaporation for the production of medical grade silicones and other fields.

Related Products

Distillation:

Under vacuum condition, distillation is used to separate the components of a compound by taking advantage of their different boiling points. The vacuum pump does further separation by its pressure change, and the vacuum equipment removes non-condensable water and light solvents from the system, allowing the extraction of the target compound from the reaction mixture. Because the boiling point is lower under vacuum, vacuum distillation is the ideal solution for handling compounds with high boiling point, heat sensitivity and explosive (e.g. active pharmaceutical ingredients).

Related Products

Solvent recovery:

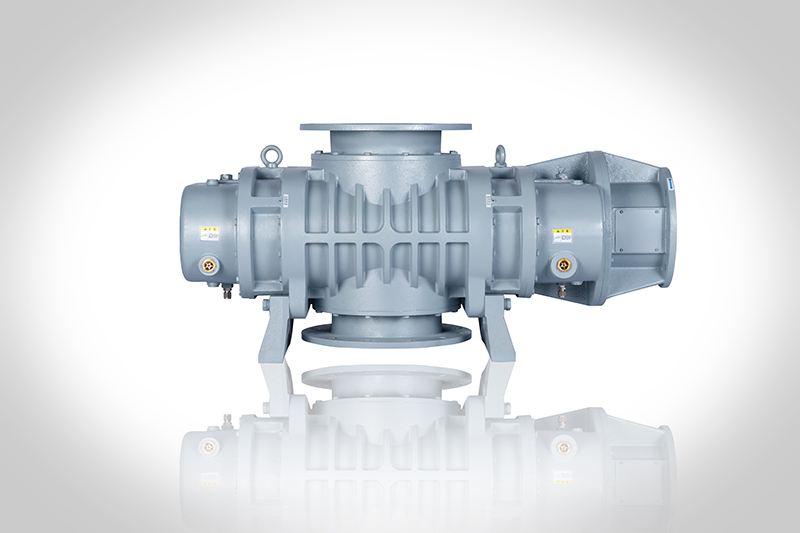

Dry vacuum pumps are the most suitable vacuum solution for solvent recovery in the pharmaceutical industry, based on their oil&water-free properties, which does not contaminate the internal sealing liquid in the process. In the pharmaceutical industry, many solvents are often flammable, explosive, toxic or environmentally hazardous and therefore need to be recovered. Vacuum pumps are mainly used to pump solvent vapors from excess solvents during filtration, washing, drying, distillation and compound synthesis in the pharmaceutical process. Dry vacuum systems can condense solvent vapors on the exhaust side to achieve solvent recovery and zero waste water discharge. For example, the recovery of acetone in the pharmaceutical industry, using the different vapor pressure of acetone gas, by adjusting the pressure and temperature to make acetone supersaturated, causing condensation to separate the mixed gas of acetone and air to a greater extent, and to recover acetone at the same time. Vacculex screw vacuum pumps are the best choice for solvent recovery in the pharmaceutical industry, with the option of adding Roots vacuum pumps (mechanical booster pumps) to increase the pumping speed and/or improve the vacuum level.

Related Products

Freeze Drying:

It is the process of removing water or other solvents from a frozen biological product by sublimation. Sublimation refers to the process by which a solvent, such as water, changes directly from a solid state to a gaseous state without going through a liquid state, like dry ice. The primary drying of freeze drying is a sublimation process, because under the vacuum condition, the boiling point of the material is lowered, the vaporization process is accelerated, and the frozen water is directly changed from the solid state to the gaseous state without going through the process of liquid state, and in the secondary drying, the deeper residual water is removed by raising the temperature and lowering the vacuum. Compared with traditional vacuum drying, freeze drying is carried out by sublimation and requires a deeper vacuum. Freeze dried materials include temperature sensitive vaccines, antibiotics and bacteria etc.

Related Products

Sterilization:

In the pharmaceutical industry, two widely used sterilization methods are ethylene oxide (EO) sterilization and steam sterilization. Ethylene oxide (EO) is a toxic, flammable gas that breaks down microorganisms at a chemical level and is used to sterilize items that may be damaged by high-temperature techniques (such as pasteurization or autoclaving), with maximum deoxygenation of the sterilization chamber (to avoid explosions). Steam sterilization, when high temperature saturated steam comes in contact with a colder object to be sterilized it will condense and absorb the heat released. This denatures the bacteria and destroys the molecular structure of their proteins, thus achieving sterilization. Vacculex dry screw vacuum pumps and liquid ring vacuum pumps are widely used in this field.

Related Products

Degassing:

Each substance varies according to temperature and pressure. A vacuum environment allows substances to evaporate at lower temperatures, the amount of dissolved gas in a liquid is proportional to its partial pressure. So, placing a solution under reduced pressure makes the dissolved gas less soluble. Degassing is the removal of dissolved or retained gases from a liquid or product. Vacuum pumps remove gases from liquids, improve their physical properties, enhance product quality for further processing, and avoid side reactions, cross-contamination or corrosion. Degassing applications for Vacculex dry vacuum pump include: removal of CO2 and other impurities in purified water production, removal of unwanted gases and liquids to improve drug quality, degassing in gelatin capsule production, etc.

Related Products

Would like to start a communication with us?

Any questions, please contact our team, we will get back to you soon.