Distillation:

Distillation is the separation of two or more layers or parts with different temperatures, pressures, compositions and phase states, separating solvents from each other through different boiling and condensing stages. Based on the characteristic that the boiling point will be lower under vacuum, it can be used in a lower temperature process environment for mild treatment of high boiling point, heat-sensitive or explosive compounds, reducing side reactions and improving product recovery when there is a maximum temperature limit, which is widely used in the extraction of natural compounds, as well as chemical synthesis, preparation of flavors and fragrances and other application fields.

Related Products

Solvent Recovery:

In the chemical industry, valuable components of the mixture evacuated from process can be reclaimed in the vacuum system through solvent recovery vacuum systems. Environmental considerations also require that the solvent-contaminated wastewater be treated, where the lower boiling fractions are evaporated and then condensed, and then transported elsewhere for further use.

Related Products

Drying:

The characteristics of vacuum drying are summarized as follows: low temperature, short drying time, mild and energy-saving. Drying in the chemical industry is mainly used for drying heat-sensitive, easily decomposed and easily oxidized substances. Benefit from the low boiling point of vacuum drying, no contact with oxygen and other characteristics, substances can ensure the integrity of the structure during the drying process. For flammable and explosive substances, it can reduce the risk of explosion and save energy. For example, for the drying of methionine in the chemical industry, Vacculex screw vacuum pumps are used to process the medium of nitrogen and water vapor.

Related Products

Degassing:

Degassing is the removal of dissolved or retained gases from a liquid or paste. Vacuum pumps remove gases from liquids to improve their physical properties, enhance product quality for further processing, and avoid side reactions, cross-contamination or corrosion. Widely used in applications such as degassing of cosmetic creams, degassing of adhesives, coatings and paints, and removal of excess gases that may cause solidifying or reduce product quality. Vacculex liquid ring pumps and screw vacuum pumps are the best choice for this application.

Related Products

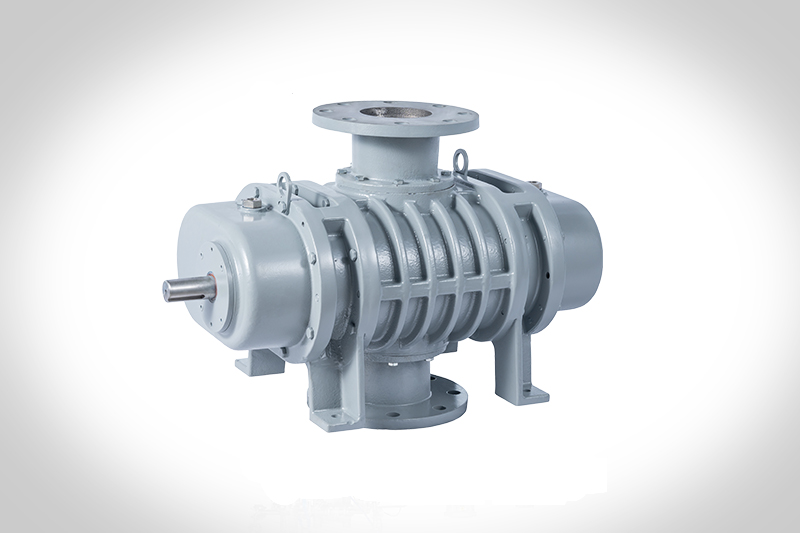

Molecular Distillation:

Molecular distillation is a special liquid-liquid separation technology, also known as short-path distillation, which is different from the traditional distillation relying on the boiling point difference separation principle, but relies on the difference in the average free path of molecular movement of different substances to achieve separation. It is characterized by low distillation temperature, high vacuum of the system, short heating time of the material, and high degree of separation; and the separation process is irreversible, without boiling bubbling phenomenon. Especially suitable for the separation of high boiling point, heat-sensitive and easily oxidized substances. Typical applications for this application include phytosterols, natural vitamins, oleochemicals, etc. Vacculex Roots vacuum pumps(mechanical vacuum booster) and liquid ring vacuum pumps are widely used in this field.

Related Products

Pneumatic Conveying:

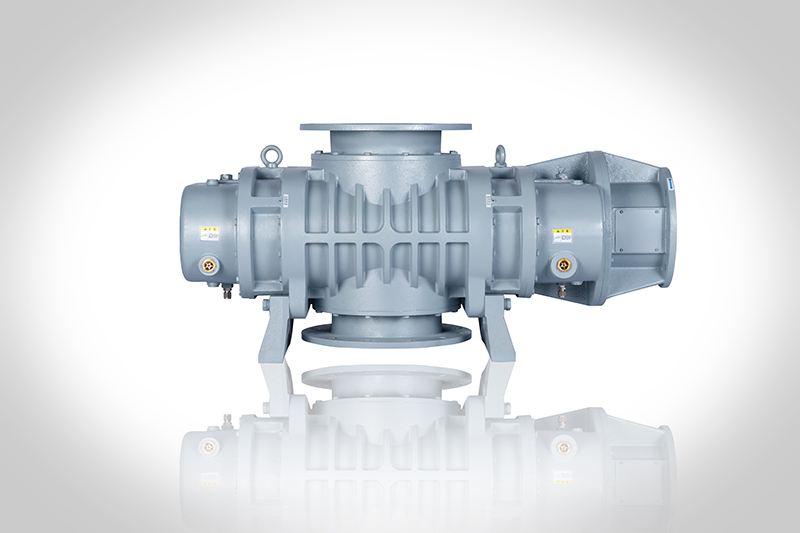

Pneumatic conveying is achieved by creating a pressure differential along the pipe and using air moving towards the low pressure area to move dry bulk materials such as cement, pulverized coal, bauxite, ammonium phosphate, potassium chloride, polyethylene and polyethylene granules, polypropylene and polypropylene granules, vinyl chloride powder, polyvinyl alcohol chips and wood chips, and various other powders and granules. Compared to mechanical conveying, the whole process is dust-free and avoids cross-contamination, thus ensuring loss-free conveying, simple piping design and reduced maintenance of rotating parts in the system. Compared to air compressors, Roots fans are more economical, requiring pressures of up to 15 psig. Vacculex’s positive displacement roots blower rotary provides constant flow regardless of pressure.

Related Products

Gas Conveying:

Blowers do pressurized conveying of gases, not for the purpose of conveying solids, but to provide (or remove) reaction gases for physical processes or chemical reactions in the system. Examples of specific applications: Polycarbonate projects, exhaust blower, incineration waste blower, bleed air blower; MMA plants, exhaust gas booster blower; Polystyrene projects, exhaust blower; Propane dehydrogenation plants, lift blower; Continuous reforming units, booster blower.

Related Products

Silicones:

Silane cracking device of silicones is negative pressure operation, vacuum pump is the key equipment of cracking device, one of the main process conditions is the vacuum level, if the vacuum value is not reached, no product will be produced, the process is rectification, and the D3/D4-DMC/HC medium is pumped and processed by Roots liquid ring system. Besides, Vacculex Roots & Screw vacuum pumps are also used in the vacuum treatment process of silicone oil removal low molecular and gross rubber dewatering. In general, in the field of silicones production, its upstream raw materials mainly use Roots pumps and liquid ring pumps, and its finished products mainly use Roots pumps and screw vacuum pumps.

Related Products

Would like to start a communication with us?

Any questions, please contact our team, we will get back to you soon.