Blog

Discovering Various Liquid Ring Vacuum Pump Applications

Liquid ring vacuum pumps are an essential component in various industrial settings. They are widely used for creating a vacuum or compressing gases in a range of applications. These pumps, also known as liquid piston rotary pumps or water ring water piston pumps, utilize a liquid as a piston to create the necessary vacuum or compression.

In the following sections, we will explore the basics of liquid ring vacuum pumps, how they work, their key components, and the various liquid ring vacuum pump applications.

The Basics of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps are a type of positive displacement pump that uses a liquid as a piston to create a vacuum or compress gases. These pumps utilize centrifugal force to generate a ring of liquid inside the pump, which acts as the piston.

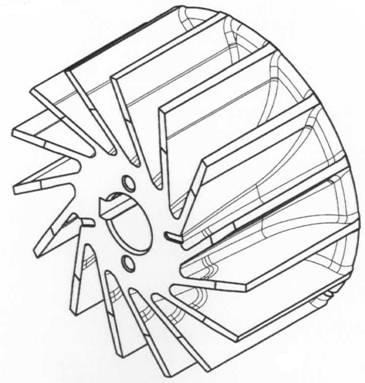

The liquid ring vacuum pump consists of an impeller, positioned eccentrically to the cylindrical housing of the pump, and two port plates. The pump is filled with liquid, typically water or a water-methanol mixture, up to a quarter of its volume. The impeller has a large number of blades, which allows for continuous operation of the pump.

When the impeller rotates, the liquid moves outward due to centrifugal force and forms a ring outside the impeller. The liquid ring is eccentric to the impeller and concentric to the housing of the pump. As the impeller rotates, gases are drawn in through the suction or inlet port, compressed, and discharged through the discharge port. The liquid ring serves as a seal, preventing any leakage of gas during the compression process.

The liquid ring vacuum pump operates on the principle of converting the kinetic energy of the rotating liquid into potential energy. This conversion creates a vacuum in the pump, allowing it to draw in gases or create compression. The continuous operation of the pump is maintained by the large number of blades on the impeller.

How Liquid Ring Vacuum Pumps Work

Liquid ring vacuum pumps work by utilizing centrifugal force to create a ring of liquid, which acts as a piston to create a vacuum or compress gases. The impeller, positioned eccentrically to the cylindrical housing of the pump, plays a crucial role in generating this liquid ring.

When the impeller rotates, the liquid inside the pump starts moving outwards due to centrifugal force. This creates a void space, and the liquid forms a ring outside the impeller. The liquid ring is eccentric to the impeller and concentric to the housing of the pump.

During the rotation of the pump, gases are drawn in through the suction or inlet port. As the impeller continues to rotate, the gases are compressed and discharged through the discharge port. The liquid ring serves as a seal, preventing any leakage of gas during the compression process.

The operation of the liquid ring vacuum pump is continuous due to the large number of blades on the impeller. This allows for efficient and effective compression of gases, making liquid ring vacuum pumps suitable for a wide range of industrial applications.

Key Components and Their Functions

Liquid ring vacuum pumps consist of several key components that work together to facilitate the operation of the pump. Each component plays a crucial role in creating the necessary vacuum or compression.

The impeller, positioned eccentrically to the cylindrical housing of the pump, is the primary component responsible for generating the centrifugal force necessary to create the liquid ring. The impeller has a large number of blades, which allows for continuous operation of the pump.

The inlet port is where the gases are drawn into the pump. This is the point where the pump creates a vacuum or compression. The discharge port is where the compressed gases are discharged from the pump.

The port plates, positioned between the impeller and the housing of the pump, feature shaped holes that enable easy discharge and suction of the vacuum pump when it is in action. These holes allow for efficient transfer of gases, ensuring smooth operation of the pump.

Advantages of Liquid Ring Vacuum Pumps in Industrial Applications

Liquid ring vacuum pumps offer several advantages that make them well-suited for various industrial applications. These advantages include:

- Low maintenance requirements: Liquid ring vacuum pumps have only one moving part, the impeller, which reduces the need for regular maintenance.

- Versatility: These pumps can handle a variety of fluids and gases, making them suitable for a wide range of industrial applications.

- Robust design: Liquid ring vacuum pumps are designed to withstand harsh environments and corrosive substances, ensuring long-lasting performance.

- Efficient operation: These pumps provide efficient vacuum or compression levels, making them ideal for industrial processes that require high performance.

- Energy savings: Liquid ring vacuum pumps can be designed to operate at different temperature ranges, allowing for energy savings and improved efficiency.

Efficiency in Various Temperature Ranges

Liquid ring vacuum pumps are known for their efficiency in various temperature ranges, making them suitable for a wide range of industrial applications. The technology used in liquid ring vacuum pumps allows them to operate at higher vacuum levels and handle different temperature extremes.

One of the key factors contributing to the efficiency of liquid ring vacuum pumps is the liquid ring itself. The liquid ring acts as a heat exchanger, absorbing heat generated during the compression process. This helps to maintain optimal operating temperatures and ensures efficient performance.

Liquid ring vacuum pumps can handle temperatures ranging from low to high, depending on the specific application. The design and construction of these pumps allow them to withstand extreme temperatures while maintaining their efficiency.

Minimal Maintenance Requirements

Liquid ring vacuum pumps have minimal maintenance requirements, making them a cost-effective choice for various industrial applications. These pumps have only one moving part, the impeller, which reduces the need for regular maintenance and lubrication.

The robust design of liquid ring vacuum pumps ensures their durability and long-lasting performance. These pumps are designed to withstand harsh environments and corrosive substances, minimizing the need for frequent repairs or replacements.

Maintenance tasks for liquid ring vacuum pumps typically include checking and replacing the sealing liquid, inspecting and cleaning the impeller and port plates, and ensuring proper lubrication of the impeller shaft bearings. The frequency of maintenance tasks may vary depending on the specific application and operating conditions.

Overall, the minimal maintenance requirements of liquid ring vacuum pumps contribute to their cost-effectiveness and reliability in various industrial applications.

Adaptability to Multiple Industries

Liquid ring vacuum pumps are highly adaptable and find applications in a wide range of industries. Their versatility and reliability make them a popular choice for various industrial processes.

These pumps are used in industries such as chemical, pharmaceutical, food processing, wastewater treatment, power generation, and more. In the chemical industry, liquid ring vacuum pumps are used for solvent recovery, vapor compression, and process vacuum. In the pharmaceutical industry, these pumps are used for vacuum distillation, moisture extraction, and vacuum condensation. In the food processing industry, liquid ring vacuum pumps are used for moisture extraction, packaging, and contamination control.

The adaptability of liquid ring vacuum pumps to multiple industries is due to their ability to handle a variety of fluids and gases, their robust design, and their efficiency in a wide range of operating conditions.

Industrial Applications of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps find extensive applications in various industrial sectors. Some of the key industries where these pumps are commonly used include:

- Chemical industry: For solvent recovery, vapor compression, and process vacuum

- Pharmaceutical industry: For vacuum distillation, moisture extraction, and vacuum condensation

- Food processing industry: For moisture extraction, packaging, and contamination control

- Wastewater treatment: For enhancements in the treatment process, such as separator vessels and partial recirculation systems

- Power generation: For improving efficiency in gas compressors, ash handling, and power generation processes

These are just a few examples of the many industrial applications where liquid ring vacuum pumps are used. Their versatility and reliability make them an essential component in various industrial processes.Vacculex’s liquid ring vacuum pumps can meet your various industrial needs. Contact our engineers now to get the latest quotation.

Chemical

Liquid ring vacuum pumps find extensive applications in the chemical industry. They are ideal for processes involving the handling of corrosive gases or vapors due to their robust design and ability to operate in harsh environments. Liquid ring technology enables efficient handling of gases with high levels of contaminants commonly found in chemical processes. These pumps are commonly used for solvent recovery, distillation, and various chemical processing applications, making them a vital component in chemical manufacturing plants.

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

Pharmaceutical

The pharmaceutical industry widely utilizes liquid ring vacuum pump applications for various critical processes such as solvent recovery, distillation, and moisture extraction. These pumps offer efficient and reliable performance, making them a preferred choice for pharmaceutical manufacturers. Liquid ring technology ensures gentle handling of delicate substances while maintaining high vacuum levels essential for pharmaceutical production. Additionally, the robust design of liquid ring vacuum pumps makes them suitable for the stringent requirements of pharmaceutical applications. Pharmaceutical companies benefit significantly from the versatility and effectiveness of these pumps.

Evaporation/Crystallization

Distillation

Solvent recovery

Freeze Drying

Sterilization

Degassing

Food Processing

Food processing industries utilize liquid ring vacuum pumps for various critical processes. These pumps efficiently aid in moisture removal, ensuring food safety and product quality. The pumps’ versatile design allows them to handle different types of fluids, making them a crucial component in the food industry. Liquid ring technology provides a reliable solution for maintaining the required vacuum levels essential for food processing operations, making them a preferred choice for several food processing applications.

Vacuum Cooling

Freeze drying

Vacuum packaging

Pneumatic conveying

Unique Applications in Environmental and Energy Sectors

Liquid ring vacuum pumps have unique applications in the environmental and energy sectors. These pumps play a crucial role in enhancing wastewater treatment processes and improving power generation efficiency.

In the wastewater treatment sector, liquid ring vacuum pumps are used for applications such as separator vessels and partial recirculation systems. These systems help in improving the treatment process by separating gas and liquid phases and recirculating the liquid for further treatment.

In the power generation sector, liquid ring vacuum pumps are used for gas compressors, ash handling, and power generation processes. These pumps help in improving efficiency, reducing energy consumption, and ensuring smooth operation in power generation plants.

Wastewater Treatment Enhancements

Wastewater treatment benefits significantly from liquid ring vacuum pumps, especially in processes requiring efficient moisture extraction and vapor compression. These pumps aid in the removal of contaminants and moisture from wastewater, contributing to improved water quality before discharge. By utilizing the sealant properties of liquid rings, these pumps effectively handle the demanding conditions of wastewater treatment plants. The robust design and versatility of liquid ring vacuum pumps make them valuable assets in enhancing wastewater treatment processes.

Wastewater Treatment

Filter Tank Air-water Backwashing

Power Generation Efficiency Improvements

Liquid ring vacuum pumps contribute to power generation efficiency by assisting in maintaining optimal pressure levels within condensers, enhancing heat transfer processes, and preventing air leakages. By efficiently removing non-condensable gases and minimizing the risk of contamination, these pumps ensure the reliable operation of power plants. Their ability to handle moisture-laden gases and volatile compounds makes them essential for improving overall efficiency in power generation processes.

Distillation

Petroleum cracking

Oil and gas recovery

Vapor Recovery

Vacuum degassing

VOC tail gas recovery

Innovations in Liquid Ring Vacuum Pump Technology

Liquid ring vacuum pumps have seen significant technological advancements in recent years, leading to improved performance and efficiency. These advancements have also paved the way for future trends in the field of liquid ring pump technology.

One recent technological advance in liquid ring vacuum pumps is the development of higher vacuum levels. Manufacturers have been able to achieve higher vacuum levels by improving the design and construction of these pumps. This allows for more efficient operation and better performance in various industrial applications.

Another technological advance is the use of cylindrical housing in liquid ring vacuum pumps. The cylindrical housing provides better sealing and ensures efficient compression of gases. This design innovation has further improved the performance and reliability of liquid ring vacuum pumps.

Total recirculation systems are another innovation in liquid ring pump technology. These systems allow for complete recirculation of the sealing liquid, reducing the need for external makeup water. The use of a heat exchanger in these systems helps to remove the heat generated during the compression process, resulting in improved efficiency.

The future trends in liquid ring vacuum pump design are focused on energy consumption and potential suppliers. Manufacturers are working towards developing more energy-efficient pumps that can reduce operating costs and environmental impact. There is also a growing demand for innovative design solutions that can meet the specific requirements of different industries.

Recent Technological Advances

Nanotechnology has revolutionized liquid ring vacuum pump design, enhancing efficiency and durability. Utilizing advanced materials such as carbon nanotubes has improved the pump’s performance in harsh environments. Additionally, the integration of smart sensors and IoT technology allows for real-time monitoring and predictive maintenance, minimizing downtime. These innovations have propelled liquid ring vacuum pumps to new heights of reliability and effectiveness in a wide range of industrial applications, ensuring optimized operations and cost savings.

Future Trends in Vacuum Pump Design

The future trends in vacuum pump design are leaning towards enhanced efficiency through the integration of advanced materials and technologies. Innovations focusing on reducing energy consumption and environmental impact are gaining precedence. Automation and remote monitoring capabilities are also becoming more prevalent, allowing for improved control and maintenance efficiency. Furthermore, there is a shift towards developing more compact and modular designs to cater to diverse industrial needs, along with a focus on increasing durability and longevity to optimize overall operational performance.

Get Quality Liquid Ring Vacuum Pumps at Vacculex

At Vacculex, you can find top-quality liquid ring vacuum pumps that are reliable and efficient for various industrial applications. These pumps are designed to provide optimal performance and durability, ensuring smooth operations and minimal maintenance requirements. With a focus on quality and innovation, Vacculex offers a range of liquid ring vacuum pumps that meet the highest standards in the industry. Whether you need a pump for packaging, material handling, or any other industrial process, Vacculex has the solution to meet your needs. Trust Vacculex for high-performance liquid ring vacuum pumps that deliver exceptional results.

Conclusion

Liquid ring vacuum pumps are versatile solutions across various industries due to their efficiency and low maintenance requirements. From chemical and pharmaceutical sectors to environmental applications like wastewater treatment, they offer reliable performance. Innovations in technology continue to enhance their functionality, ensuring optimal performance and energy efficiency. Whether in power generation or food processing, these pumps demonstrate adaptability and robustness. The future holds promising advancements in vacuum pump design, catering to evolving industrial demands. The unique ability of liquid ring vacuum pumps to operate effectively in harsh environments makes them a preferred choice for diverse applications.