Distillation:

Through atmospheric distillation or vacuum distillation, or two distillations (atmospheric + vacuum distillation), fuel oil is processed to make gasoline and other hydrocarbon fuels. The crude oil contains heavier and lighter hydrocarbons with different boiling points. Vacuum distillation separates the heavy hydrocarbons and extracts the lighter components such as gasoline, making the whole process energy efficient and reducing the production of unwanted by-products.

Related Products

Petroleum cracking:

The process of breaking hydrocarbons with long-chain molecules into various short-chain gaseous hydrocarbons and small amounts of liquid hydrocarbons to provide organic chemical raw materials is called petroleum cracking in industry. The petroleum processing process, in which short-chain unsaturated hydrocarbons are obtained as the main component, is a chemical change. The resulting cracked gas is a complex mixture of gases, which contains mainly unsaturated hydrocarbons such as ethylene, propylene and butadiene, but also methane, ethane, hydrogen and hydrogen sulfide. By separating the cracking products, the required variety of raw materials can be obtained. These raw materials are widely used in synthetic fiber industry, plastic industry, rubber industry, etc.

Related Products

Oil and gas recovery:

In the process of oil storage, loading and unloading, transportation, etc., a large amount of oil and gas will be generated due to its volatility. Therefore, the above process is often equipped with oil and gas recovery devices to collect oil and gas, on the one hand to reduce oil and gas pollution and safety hazards, etc., and at the same time can reduce oil loss and increase efficiency. The vacuum pump is mainly responsible for the function of desorption. After the adsorption tank is saturated, a high vacuum is needed to separate the oil vapor from the adsorbent, and it is also the regeneration process of the adsorption tank. Through the vacuum pump, the adsorption tank can be brought to a high vacuum state and the adsorbed oil vapor is desorbed from the adsorbent. After the pressure in the tank drops to a certain level, a small amount of nitrogen or air can be passed into the adsorption tower as cleaning gas to promote further desorption of the oil vapor. The oil and gas desorbed from the adsorbent can be sent to the recovery process as a concentrated gasoline vapor containing almost no air. Vacculex dry screw vacuum pumps are widely used in this field.

Related Products

Vapor Recovery:

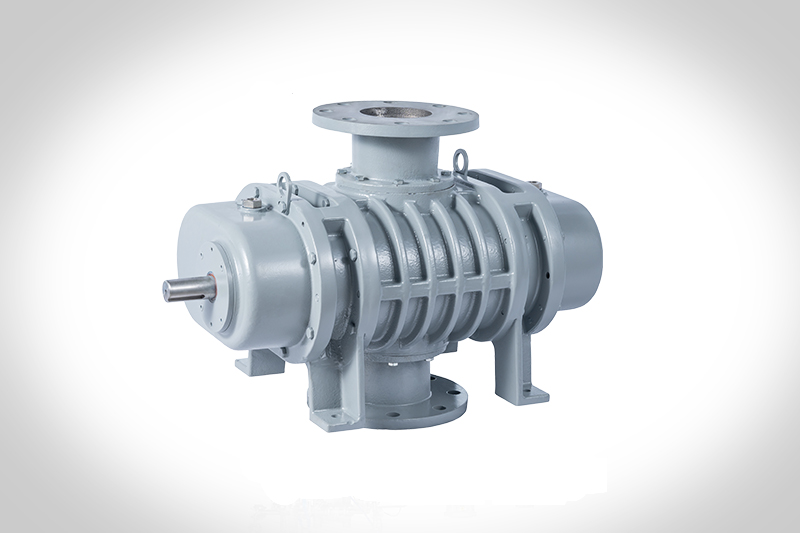

Vapor recovery is the process of removing harmful vapors and fluid contaminants from crude oil products to improve purity and prevent the release of toxic contaminants into the environment. Vapor recovery is particularly important because over time, internal vapor pressure increases and hydrocarbon storage vessels may tend to leak through safety valves and hatches. Vacculex Roots blowers are commonly used in vapor recovery to raise the pressure in the pipeline and push the gas into another process that can be reused or sent to a natural gas compressor.

Related Products

Vacuum degassing:

Degassing is the removal of dissolved, residual gases in the liquid or product. Vacuum devices can remove gas from liquids, improve their physical indicators, improve product quality, and avoid pollution or corrosion from the release of residual gas in products. For example: oil degassing to improve purity (hydrocarbon oil, insulating oil, turbine oil, brake fluid and hydraulic oil, etc.)

Related Products

VOC tail gas recovery:

Petroleum refining and petrochemical processes are the main cause of volatile organic compounds (VOCs) generated, the composition of the exhaust gas is complex, the petrochemical industry’s exhaust gas has high toxicity, wide sources, complexity, difficulty in treatment etc. The conventional application is to use Vacculex Roots blower to blow it into the RTO furnace for full combustion, through the heating of the thermal storage ceramic on the organic exhaust gas after high-temperature treatment, will be decomposed into carbon dioxide and water or non-toxic and harmless high-temperature flue gas.

Related Products

Would like to start a communication with us?

Any questions, please contact our team, we will get back to you soon.