Blog

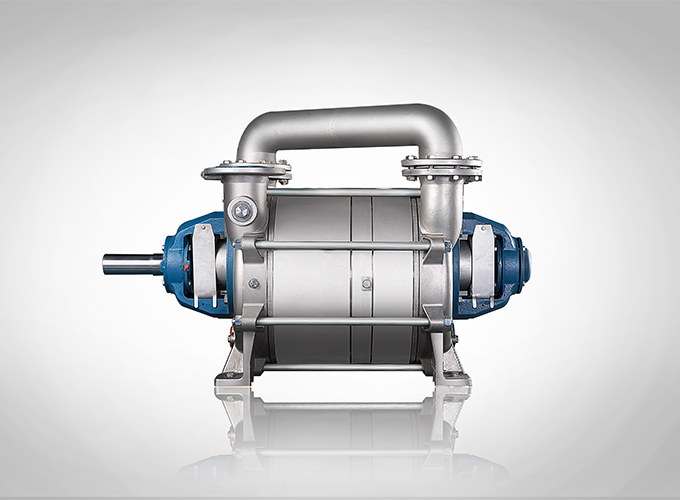

Liquid Ring Vacuum Pump: How it Works

Liquid ring vacuum pumps are widely used in various industries for applications that require the removal of gas or vapour from a system. These pumps operate based on the principle of centrifugal force, creating a vacuum by the discharge of compressed gas. Understanding the working principle and types of liquid ring vacuum pumps can provide valuable insights into their applications and benefits. In this blog, we will explore liquid ring vacuum pump working principle, the different types available, and their applications in various industries, including their ability to handle condensable vapour.

Understanding Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps find use in various industrial applications due to their versatile nature. These pumps create a very smooth ring of liquid at the top of the vacuum pump, forming an area of void space for gas compression. The sealant liquid, commonly used in industrial applications, circulates from the bottom to the top of the pump, aiding the impeller rotation to produce a vacuum. Understanding the basic concept is crucial as the impeller, situated at the top of the pump, rotates in a clockwise direction inside the cylindrical housing. This rotation, along with the centrifugal force, helps in compressing the gas and creating a vacuum at the top of an impeller. The compressing happens as the gas is forced outside the sides of the impeller due to centrifugal force, and the smooth ring of liquid aids in the process, making liquid ring vacuum pumps integral to various industries.

Definition and Basic Concept

The operation of a liquid ring vacuum pump relies on the principle of centrifugal force, where gas compression is facilitated by the discharge of gas. These vacuum pump systems utilize liquid as the functional component, forming a sealant liquid ring essential for the compression process. The inlet port, also known as the suction port, allows gas to enter the pump, while the discharge port expels the compressed gas in liquid form. It’s important to note that liquid ring vacuum pumps create a very smooth ring of liquid, enabling impeller rotation to generate vacuum. This process is crucial in various industrial applications, making liquid ring vacuum pumps widely used and highly efficient.

Types of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps can be broadly classified into two types: single-stage and two-stage liquid ring pumps.

Single-stage liquid ring pumps are commonly used in applications where the vacuum level required is near atmospheric pressure. These pumps operate by creating a vacuum through the compression of gas using a liquid sealant ring. The single-stage liquid ring pump design, with its simplicity and reliability, makes it suitable for a variety of industrial applications. Another type of liquid ring vacuum pump is the Nash pump, named after its inventor Lewis H. Nash. This pump was patented in 1914 and manufactured by the Nash Engineering Company in Norwalk, Connecticut.

On the other hand, two-stage liquid ring pumps offer enhanced vacuum performance and efficiency. These pumps are capable of achieving deeper vacuum levels, making them suitable for demanding industrial processes that require stringent vacuum requirements. The two-stage design allows for improved gas compression, resulting in higher vacuum levels and increased process productivity.

Two-Stage Liquid Ring Pump

The two-stage liquid ring pump is a specialized vacuum pump that offers superior vacuum performance, making it ideal for various industrial applications. This type of pump typically consists of two impellers arranged in series, each contributing to the compression process.

In a two-stage liquid ring pump, the sealant liquid creates the liquid ring, which is necessary for the compression process. The impeller blades of the first stage impeller force the gas towards the discharge port, compressing it and reducing the vapor pressure inside the pump. The compressed gas then passes through the second-stage impeller, further increasing the pressure and creating the desired vacuum level. To better understand the process, refer to the diagrams below.

By utilizing the sealant liquid and the rotation of the impeller blades, the two-stage liquid ring pump efficiently compresses gas, resulting in high vacuum levels. These pumps are commonly used in industrial applications where deep vacuum levels are required, such as beverage processing, packaging, and mining.

Single-Stage Liquid Ring Pump

Single-stage liquid ring pumps are widely used in industrial applications that require vacuum levels near atmospheric pressure. These pumps operate by creating a very smooth ring of liquid, also known as the liquid ring, which facilitates gas compression.

The liquid ring acts as the sealant liquid, preventing the gas from escaping during compression. However, it should be noted that some liquid carryover can occur, especially for applications with high amounts of vapor. To mitigate this, the liquid ring pump systems incorporate port plates, which separate the liquid ring from the process gas, allowing for efficient gas compression without contamination.

Single-stage liquid ring pumps offer simplicity, reliability, and ease of maintenance, making them suitable for a range of industrial applications. These pumps find applications in industries such as pulp and paper, packaging, and air conditioning, where they provide cost-effective and robust vacuum solutions.

The Working Principle of Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps work on the principle of centrifugal force, creating a vacuum by compressing gas using a liquid sealant ring. The vacuum pump’s impeller, typically located inside a cylindrical housing, rotates, creating a void space between the impeller blades.

The formation of the liquid ring, the rotation of the impeller, and the compression step are instrumental in the pump’s functionality. As the impeller rotates, the centrifugal force generated forces the sealant liquid to the sides of the impeller and the separator vessel. This process creates the liquid ring, which serves as the seal and compression medium for gas and vapor. The impeller vane plays a crucial role in this process, as it helps to create the void space and maintain the liquid ring’s shape. Additionally, the seal liquid is responsible for forming the ring inside the pump body and creating small chambers for gas to be trapped, allowing for the compression of the gas and the pumping action.

Step-by-step Process

- Several factors influence the performance of liquid ring vacuum pumps, including the electrical power input, the specific process vacuum requirements, atmospheric pressure, and the type of gas being compressed. Here are some key factors that can affect the pump’s performance:

- Electrical power input: The power input to the liquid ring vacuum pump affects its capacity to handle gas compression and maintain the desired vacuum levels. Higher power input can result in improved pump performance.

- Process vacuum requirements: The process vacuum requirements, such as those in beverage processing applications, play a crucial role in determining the appropriate liquid ring pump and optimizing its performance.

- Atmospheric pressure: The pressure of the environment in which the liquid ring vacuum pump operates, specifically the atmospheric pressure, affects the vacuum level achievable by the pump.

- Type of gas being compressed: The type of gas being compressed can have an impact on the liquid ring pump’s efficiency and performance. Different gases have varied compression requirements, and the pump’s design should accommodate the specific gas characteristics.

- By considering these factors, operators of liquid ring vacuum pumps can optimize performance, enhance energy efficiency, and achieve the desired vacuum levels for their specific applications.

The Benefits of Using Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps offer several advantages over other vacuum pump systems, making them a preferred choice for many industrial applications. Some of the benefits of using liquid ring vacuum pumps include:

- Efficiency and Energy Saving: liquid ring vacuum pumps are designed for energy-efficient operation, minimizing power consumption and reducing operating costs.

- Versatility in Applications: liquid ring vacuum pumps find applications in a wide range of industrial processes due to their versatility and suitability for handling different gas and vapor mixtures.

Efficiency and Energy Saving

One of the notable benefits of liquid ring vacuum pumps is their energy-saving capabilities. These pumps are designed to minimize power consumption, resulting in reduced energy costs for industrial applications.

The unique design of liquid ring vacuum pumps reduces sliding friction and eliminates the need for shaft seals, further contributing to energy savings. By maximizing efficiency, liquid ring vacuum pumps offer optimal gas compression with minimal energy consumption, making them an environmentally-friendly and cost-effective choice for vacuum applications.

Versatility in Applications

Liquid ring vacuum pumps are widely used across various industrial applications due to their versatility. These pumps can handle a wide range of gas and vapor mixtures, making them suitable for diverse industrial processes.

Their ability to handle different vapor pressures and contaminants makes liquid ring vacuum pumps the preferred choice for applications such as beverage processing, packaging, pulp and paper, chemical processing, and water treatment. The versatility of liquid ring vacuum pumps enables efficient and reliable vacuum solutions, ensuring the smooth operation of different industrial processes.

Application of Liquid Ring Vacuum Pumps in Various Industries

Liquid ring vacuum pumps find applications in various industries, contributing to the efficiency and reliability of critical processes. Let’s explore some of the industries that extensively use liquid ring vacuum pumps:

In the Aircraft Industry

Liquid ring vacuum pumps play a crucial role in the aircraft industry, being used for various applications such as vapor recovery, de-icing systems, and waste extraction. Their ability to handle wet or dry vapors makes them suitable for diverse aircraft system requirements, while their operational reliability under extreme conditions ensures the safety and efficiency of critical aircraft operations. The efficiency and safety features of these pumps make them an ideal choice for maintaining operational standards in the aircraft industry.

In the Automobile Industry

Liquid ring vacuum pumps are essential in the automobile industry for applications such as brake system vacuum assist and emissions control. Their ability to handle liquid and vapor mixtures makes them suitable for diverse automotive applications. The compact design and efficient operation of these pumps meet the stringent performance requirements of the automotive industry, contributing to the reliability and optimal functionality of essential automotive systems. Their versatility and robustness make them indispensable for critical applications in the automobile industry.

In the Chemical Industry

The industrial applications of liquid ring vacuum pumps in the chemical industry are diverse and crucial. For instance, these pumps are widely used for solvent recovery, vacuum distillation, and filtration processes. Their capability to handle corrosive and hazardous gases makes them perfectly aligned with the demanding requirements of chemical processing applications. Moreover, the ability of the vacuum system to operate with a liquid sealant makes it well-suited for managing challenging chemical process conditions. By contributing to the safety, efficiency, and environmental compliance of various chemical processing operations, liquid ring vacuum pumps play a pivotal role in enabling reliable and efficient processing of a wide range of chemicals in the chemical industry.

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

In the Water Treatment Industry

In the water treatment industry, the most commonly used liquid ring vacuum pumps are essential for applications such as wastewater evaporation and filtration systems. Their ability to handle liquid carryover and contaminants makes them ideal for the diverse challenges in water treatment. These vacuum pumps contribute to the efficiency and sustainability of water treatment processes, ensuring effective resource management and maintaining the integrity of essential water treatment systems. Additionally, their versatility and effectiveness support the sustainable management of water resources in the industry. The very smooth ring of liquid created by the pumps is crucial in managing contamination effectively, making them indispensable for maintaining the quality and safety standards in water treatment processes.

Wastewater Treatment

Filter Tank Air-water Backwashing

How Does a Liquid Ring Vacuum Pump Differ from Other Vacuum Pumps?

Liquid ring vacuum pumps offer distinct advantages that differentiate them from other vacuum pump systems. The key differences lie in the sides of the impeller, the separator vessel, the ring shape, and the most commonly used liquid sealant.

Unlike dry vacuum pumps, liquid ring vacuum pumps can handle liquid and vapor mixtures without the risk of contamination or damage. The liquid ring vacuum pump’s impeller rotation forces the liquid sealant to the sides of the impeller and the separator vessel, creating the liquid ring shape required for effective gas compression.

Additionally, the liquid sealant used in liquid ring vacuum pumps, such as water or other compatible liquids, acts as the most commonly used sealant. This liquid ring shape, coupled with the rotation of the impeller, enables efficient compression of gases and vapors, delivering reliable vacuum solutions across various industrial applications.

Conclusion

In conclusion, liquid ring vacuum pumps are versatile and efficient tools that find applications in various industries. They work on the principle of creating a liquid ring that helps generate the required vacuum pressure for different processes. With their energy-saving capabilities and wide range of applications, these pumps are a popular choice in industries such as aerospace, automotive, chemical, and water treatment.

If you are looking for a reliable and efficient liquid ring vacuum pump for your industry, consider getting quotes from our trusted suppliers. They can provide you with the best commercial options that meet your specific requirements. Don’t miss out on the benefits of using a liquid ring vacuum pump in your operations. Get in touch with our experts today to explore your options.