Vacuum Cooling:

The main advantages of the vacuum cooling process are low energy consumption, fast refrigeration time and a significant increase in shelf life. For example, leafy vegetables can easily lose their freshness and rot after harvesting. If large quantities are cooled by traditional cooling methods, which usually take several hours or more, the cooling time can be significantly reduced by using vacuum cooling, which takes advantage of the low boiling point of water under vacuum. Under vacuum, the moisture on the surface and inside of crops begins to evaporate and is pumped out together with the air by the vacuum pump. Then, for example, bread and sushi rice speed up the processing and extend the shelf life. Vacculecx screw vacuum pump play an important role in this field based on its high pumping speed and water vapor tolerance.

Related Products

Freeze drying:

The primary drying of freeze drying is a sublimation process, because under vacuum conditions, the boiling point of the material is lowered, the vaporization process is accelerated, and the frozen water is directly changed from a solid state to a gaseous state without going through the process of liquid state. In the secondary drying, the deeper residual moisture is then removed by raising the temperature and lowering the vacuum. This application is suitable for fruits and berries as well as cooked meat or vegetables. Also herbs and spices can be preserved by freeze drying. Vacculex dry screw vacuum pumps with variable frequency motor are a good choice for this application and can also be combined with Roots vacuum pumps (mechanical booster pumps) to achieve higher vacuum levels.

Related Products

Vacuum packaging:

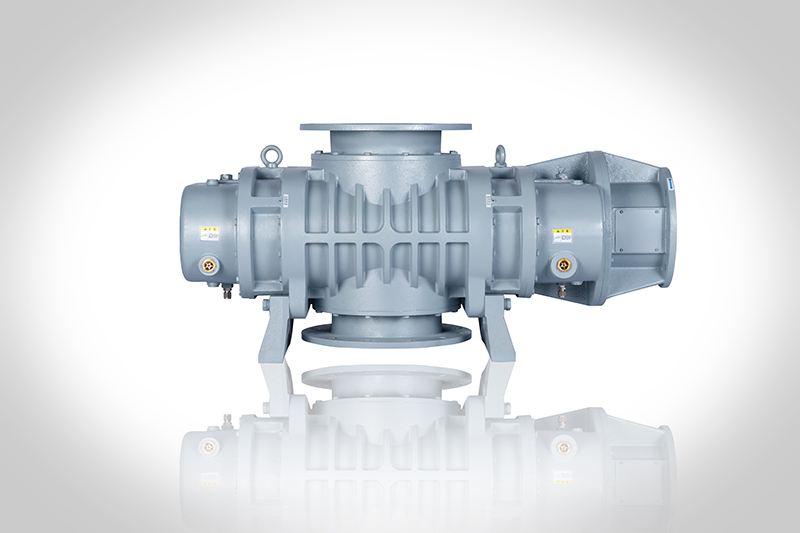

A packaging process that removing air from the package and removing water, vapor, fat, and granular materials prior to sealing to prevent the growth of aerobic bacteria, thereby preventing oxidation and degradation of the product and extending the shelf life of the product. Vacuum often plays an important role in the packaging process. For example, vacuum is used for thermoforming in the production of packaging. Vacuum is also used for tray sealing, chamber packaging, bag packaging machines and many other packaging applications. Vacculex dry vacuum pumps are used in a wide range of food vacuum packaging applications, and roots blowers are also used in low vacuum applications for packaging and handling to filter out impurities and dust.

Related Products

Pneumatic conveying:

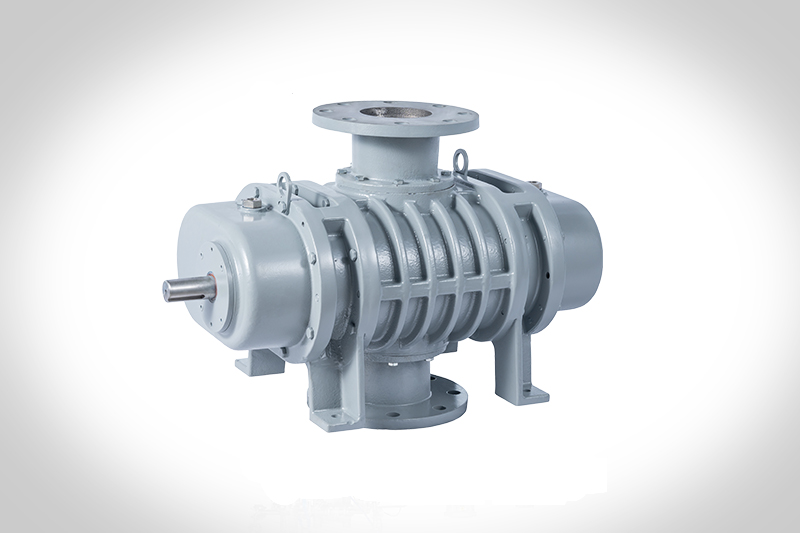

Pneumatic conveying is achieved by creating a pressure difference along a pipe and moving dry bulk materials using air moving to a low-pressure area to safely and economically convey dusts, powders, granules and other fluidizable materials, such as soybeans, corn, wheat, flour, alkali powder and other powder and granular materials. The entire process of pneumatic conveying is dust-free, avoiding cross-contamination and thus ensuring loss-free conveying, simple piping design and reduced maintenance of rotating parts in the system. Vacculex Roots blowers offer a cost-effective solution compared to the high-pressure sources of air compressors, requiring pressures of up to 15 psig.

Related Products

Would like to start a communication with us?

Any questions, please contact our team, we will get back to you soon.