Crystal growth:

The growth of semiconductor single crystals with controllable crystal orientation, components, impurities, defects, geometry and size, including single crystal and thin film single crystal, is the main process of semiconductor material preparation. The process of large-scale industrial production of semiconductors requires a high-quality clean environment and high-precision control technology, which places high demands on vacuum systems and computer control systems. Existing crystal growth equipment currently commonly uses dry vacuum pump to constitute the evacuation system.

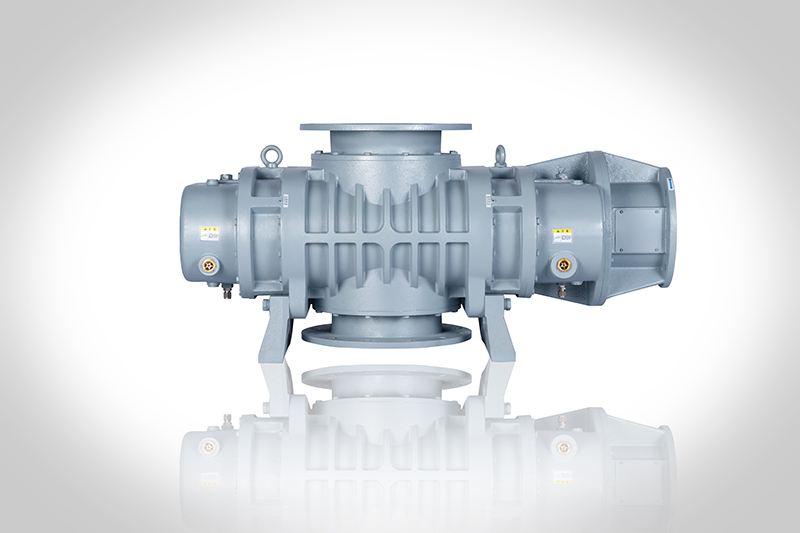

Related Products

Deposition:

Deposition can be divided into physical vapor deposition (PVD) process, chemical vapor deposition (CVD) process and atomic layer deposition (ALD) process according to different process principles. PVD process usually operates under high vacuum below 10-3 to 10-7 Torr; CVD includes PECVD, SACVD, LPCVD, etc., most of processes operate under primary vacuum; ALD (Atomic Layer Deposition) process, most ALD processes operates under primary vacuum in the pressure range of 10-1 to 5 mbar.

Related Products

Etching:

Dry etching is a process technology method that uses plasma generated in the gaseous state to selectively etch away the exposed surface material on the wafer by physical and chemical reactions with the wafer exposed to the plasma through the window of the mask layer opened by lithography. According to the material of the surface material to be removed, different vacuum levels are required, and the process is generally performed at vacuum levels in the range of 10-2 to 10-3 mbar.

Related Products

Wafer movement:

Wafers are transferred between chambers by a transfer mechanism under vacuum, or in and out of the semiconductor tool by a load lock chamber pumped to a high vacuum pressure, which needs to be maintained throughout the entire process, usually at a vacuum level between 10-1 and 10-2 mbar.

Related Products

Vacuum sintering:

Vacuum sintering is the sintering of materials under vacuum or the agglomeration of powder particles into aggregates of crystals to obtain the desired physical and mechanical properties of the product or material. Vacuum can improve the wettability of the liquid phase to the solid phase, which is beneficial to shrinkage and improve the organization of the material, and has obvious effect on improving product quality. Here it is mainly used for the sintering process of semiconductor components and power rectifier parts.

Related Products

Would like to start a communication with us?

Any questions, please contact our team, we will get back to you soon.