Blog

What Is Roots Vacuum Pump: Working Principle, Advantage & Application

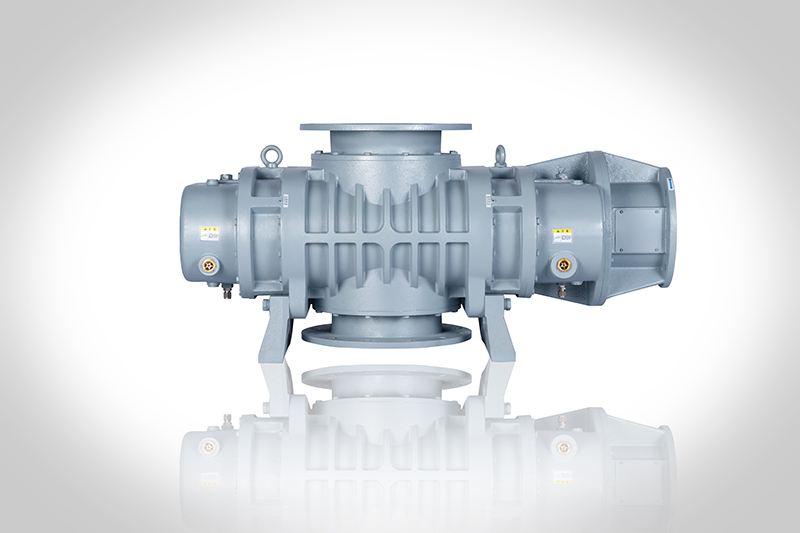

Roots Vacuum Pumps are an essential component of many industrial processes, from vacuum metallurgy smelting to chemical processing. But what exactly is a Roots Vacuum Pump, and how does it work? In this blog post, we’ll explore the inner workings of Roots Vacuum Pumps and discuss the advantages they offer over other types of vacuum pumps. We’ll also dive into the different types of Roots Vacuum Pumps available on the market today and their various applications across industries. Whether you’re a seasoned engineer or just starting out in your field, this guide will provide you with a comprehensive understanding of Roots Vacuum Pumps and their critical role in modern manufacturing processes.

What is a Roots Vacuum Pump?

A Roots Vacuum Pump is a mechanical vacuum pump that uses two rotating rotors to create a vacuum. It has high pumping speeds and low ultimate pressures, making it ideal for industrial applications like semiconductor manufacturing and chemical processing. The pump is oil-free, quiet, and requires minimal maintenance.

How Does a Roots Pump Work

A Roots Vacuum Pump is a type of mechanical vacuum pump that creates a vacuum by using two rotating rotors moving in opposite directions to compress air between their lobes. It achieves high pumping speeds and low ultimate pressures that are suitable for various industrial applications like chemical processing, semiconductor manufacturing, and food packaging. The working principle involves trapping air between rotor lobes during rotation to create a vacuum with improved efficiency compared to other types of pumps. The Roots Vacuum Pump operates smoothly with reduced noise levels while providing continuous operation without requiring lubrication or oil-sealed mechanisms. Its unique design allows it to reach high pumping speeds and lower pressure levels than other pumps within its pressure range.

Advantages of a Roots Vacuum Pump

Roots Vacuum Pumps are an ideal solution for creating a high-volume, low-pressure vacuum. Their operating principle involves two rotors rotating in opposite directions to compress air between them and create a vacuum. Unlike other types of pumps, Roots Vacuum Pumps operate without oil, making them more cost-effective and less prone to contamination risks. They offer several key advantages, including high pumping speed, low ultimate pressure, and reduced noise levels compared to other types of pumps. Additionally, they are versatile and can be used in a wide range of applications, from semiconductor manufacturing to food packaging.

Higher Operating Efficiencies

Roots vacuum pumps are well-known for their high operating efficiencies, thanks to their simple design with few moving parts. This design makes them more reliable and easier to maintain than other types of pumps. Due to their ability to handle large volumes of gas and air while minimizing the risk of contamination or equipment damage, these pumps are suitable for continuous industrial applications like chemical processing, pharmaceutical manufacturing, and food production. Moreover, their high efficiency and reliability make them an excellent choice for such applications.

Reduced Noise

Roots vacuum pumps are widely known for their low noise level, making them an ideal choice for applications where noise pollution is regulated or where workers need to communicate effectively without interference from machinery. The use of two rotors with equal numbers of teeth in Roots vacuum pumps helps reduce noise and vibration while allowing for high pumping speeds and improved efficiency. This efficient design with few moving parts makes Roots Vacuum Pumps more reliable and easier to maintain compared to other types of vacuum pumps. Reduced noise levels make it an excellent option for high-vacuum applications such as thermal expansion and degassing in the medium vacuum range.

Lower Cost

Roots Vacuum Pumps are a cost-efficient option when compared to other vacuum pumps as they require less maintenance, have a longer lifespan and can operate continuously without regular cooling breaks. Their efficiency is due to their simple design with few moving parts that can handle large volumes of gas and air with minimal risk of contamination or damage. This makes Roots Vacuum Pumps an ideal choice for businesses looking to save on equipment expenses while maintaining high performance levels. In addition, the lower cost of Roots Vacuum Pumps makes them an attractive option for many industries such as chemical processing and pharmaceutical manufacturing.

Types of Roots Vacuum Pumps

Roots vacuum pumps are available in different types to suit different applications. These include conventional Roots vacuum pumps, multi-stage roots vacuum pumps that improve efficiency and increase the level of vacuum by adding more stages, dry roots vacuum pumps that eliminate the need for oil and reduce maintenance, liquid ring roots vacuum pumps that use liquid as a sealing medium suitable for handling wet or corrosive gases, and customized roots vacuum pumps designed for specific industrial requirements.

Low-vacuum Roots Vacuum Pump

Low-vacuum Roots Vacuum Pumps are an excellent choice for industrial processes requiring low-level vacuum. They provide a vacuum level of 10^-2 to 10^-3 torr and have a straightforward design with no moving parts. This simplicity makes them easy to operate, and they can run continuously without the need for maintenance or oil changes. One of the key benefits of Low-vacuum Roots Vacuum Pumps is their high pumping speed, which makes them efficient even in demanding applications such as vacuum drying, degassing, and impregnation. These pumps are also energy-efficient, making them a cost-effective option compared to other types of pumps.

Medium Vacuum Roots Vacuum Pump

Medium Vacuum Roots Vacuum Pumps are ideal for applications that demand a vacuum level that is neither too high nor too low. They comprise two or more rotors that rotate in opposite directions to produce a vacuum. These pumps find extensive use in industries such as food processing, pharmaceuticals, and chemical processing due to their high pumping speed and low maintenance needs.

When selecting a Roots Vacuum Pump for your operations, it is prudent to take into account criteria like the desired level of vacuum and the specific application. Additionally, these pumps can work optimally with backing pumps like rotary vane pumps or diaphragm pumps for an optimal compression ratio.

High-Vacuum Roots Vacuum Pump

High-vacuum Roots vacuum pumps are ideal for creating extremely low pressures in various industrial applications. The pump uses an interlocking rotor system that rotates in opposite directions to move air from the inlet to the outlet, creating a pressure drop along the way. These pumps are commonly used in industries such as semiconductor manufacturing, vacuum coating, and others with high pumping speeds and low ultimate pressure requirements. High-vacuum Roots vacuum pumps compress gas without oil lubrication by using dry pumps or mechanical booster backing pumps. They also have interstage overflow valves to prevent over-compression and can be operated continuously for long periods without requiring maintenance or oil changes.

Application of Roots Pump Work

Roots vacuum pumps find extensive use in various industrial processes like vacuum metallurgy smelting, degassing, rolling, and chemical processing. These pumps create a pressure difference between two chambers, forcing gas to move from the inlet to the outlet. Roots pumps offer several benefits such as high pumping speed, low noise levels, and minimal vibration. They are ideal for high-volume pumping of gases and vapors with low molecular weights. Roots vacuum pumps come in different types like low-vacuum Roots vacuum pump, medium vacuum Roots vacuum pump, and high-vacuum Roots vacuum pump. When selecting a Roots Vacuum Pump for your specific application, factors such as operating principle, required vacuum level, and ultimate pressure should be considered.

Vacuum Metallurgy Smelting

Vacuum metallurgy smelting is a critical industrial application that demands high efficiency and quality. In this process, the presence of impurities can severely impact the final product’s properties. Roots vacuum pumps come with an oil-free design, which prevents contamination by oil or any other foreign particle. These pumps have a high pumping speed, making them ideal for efficient removal of gas and vapor from the smelting chamber. This feature is particularly useful as it helps maintain a clean environment with minimal leakages, ensuring that the end product is of optimum quality.

Degassing

Efficient degassing is crucial in industries like chemical and pharmaceutical manufacturing. Roots vacuum pumps can effectively create a low-pressure environment by removing gas and vapor from a sealed chamber. The pump’s unique design with two rotating lobes generates high pumping speed, pulling gas or vapor through the inlet port and discharging it out through the exhaust port. This process can efficiently eliminate any form of contamination present in the sealed area. The pumps operate quietly and without vibration while providing energy efficiency, making them ideal for continuous operation. Using these oil-free pumps prevents contamination of end products, which ensures high-quality results.

Rolling

Roots vacuum pumps are crucial in rolling processes for steel, aluminum, and copper mills. They aid by creating low-pressure environments that help remove air from the system, leading to better-formed products. These pumps operate on the principle of using two rotating lobes that rotate in opposite directions to create suction and discharge through inlet and exhaust ports. Besides their high pumping speeds and large volume handling capacity, these pumps come with additional benefits such as low noise, compact design, and oil-free operation. With their ability to handle high volumes of gas, Roots vacuum pumps offer improved product quality, reduced energy consumption while operating at higher efficiencies; making them an ideal choice for rolling processes.

Chemical Processing

Roots vacuum pumps play a crucial role in the chemical processing industry. These pumps work with gases and vapors, making them ideal for handling various chemicals. Operating at pressures down to 10^-3 Torr, they allow for efficient handling of corrosive or reactive gases that are common in the industry. With high pumping speeds and oil-free operation, roots vacuum pumps provide greater productivity and faster processing times, improving the bottom line of chemical manufacturing facilities. They are often preferred over other types of pumps due to their ability to handle large volumes of gas while remaining compact in size.

Frequently Asked Questions

What are the advantages of using a roots vacuum pump in industrial applications?

Using a roots vacuum pump in industrial applications offers several advantages. They are oil-free which is perfect for industries where contamination is an issue. Additionally, roots vacuum pumps operate quietly, require minimal maintenance and have a high pumping speed. They are commonly used in chemical processing, semiconductor manufacturing, and food packaging as they can achieve a high vacuum level quickly.

What industries commonly use roots vacuum pumps?

Roots vacuum pumps are widely used in industries that require high vacuum levels, such as semiconductor manufacturing and aerospace. They’re also utilized in various other industries, including chemical, pharmaceutical, metallurgy, food processing, and environmental protection. These pumps are ideal for applications that need high pumping speeds and low ultimate pressures, such as degassing, drying, distillation, and freeze-drying.

What is the pressure of Roots vacuum pump?

The pressure of a Roots vacuum pump can differ depending on the model and usage. These pumps can typically reach pressures as low as 10^-3 mbar, but the required pressure may vary based on the application. It is crucial to select the right pump for optimal performance.

Conclusion

Roots vacuum pumps are widely used in various fields, such as metallurgy smelting, degassing, and chemical processing. The most significant advantage of the Roots pump is its high efficiency and low noise. Its cost-effectiveness makes it an ideal choice for many industrial applications. There are three types of Roots vacuum pumps available in the market that cater to different applications – low-vacuum, medium-vacuum, and high-vacuum Roots vacuum pumps. If you’re looking for a reliable and efficient solution for your industrial needs, get in touch with us for a quote today. Our experts can help you choose the right Roots vacuum pump for your business needs.

Contact Our Support Team