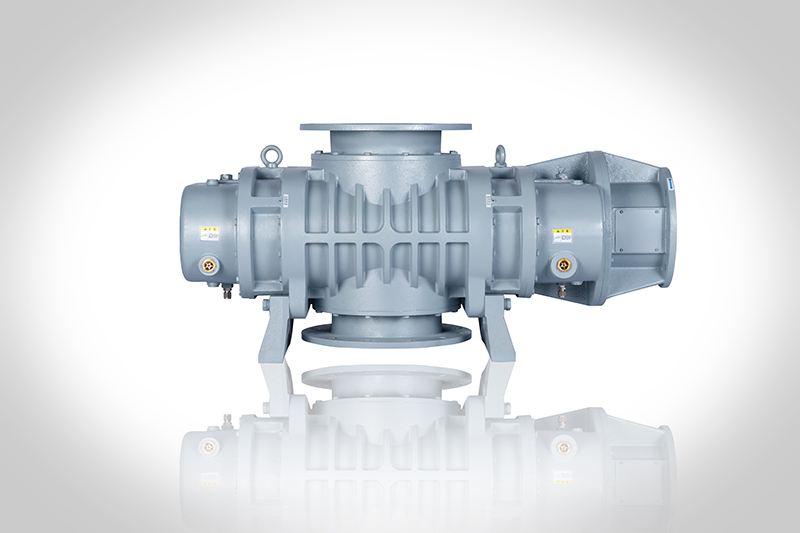

Roots Vacuum Pump

Roots vacuum pump (also called mechanical vacuum booster), As the main pumping equipment to obtain medium and high vacuum, is a positive-displacement vacuum pump and an oil-free dry vacuum pump.

Vacculex

About Roots Vacuum Pump

As the main pumping equipment to obtain medium and high vacuum, roots vacuum pump is a positive-displacement vacuum pump. The Roots vacuum pump is a low cost equipment with high pumping speed in the vacuum range of 0.001mbar~120mbar and can be combined with various vacuum pumps to form vacuum units, also can be combined with multi-stage Roots pumps to improve the system vacuum and achieve energy saving according to the actual situation.

Find out How Our Roots Vacuum Pumps Work

- One-piece double impeller, impeller and shaft are cast in one piece. The rotor has internal straight-through cavity with optional sealing plate design.

- Five point bearings design, high reliability.

- Special seal structure, the surface of the shaft in contact with the seal is polished to improve operating life and achieve zero leakage, eliminating cross contamination of oil and process gas.

- Synchronous gear is helical gear design, and installed at the drive end to reduce the distortion and deformation of the impeller, to improve the silence, stability and reliability.

- Double oil tank design can achieve sufficient lubrication, improve stability, optional cooling methods: air cooling, water cooling.

Select our Roots Vacuum Pump

Five-point bearing design, double oil tank, nitrogen gas barrier, suitable for high temperature/high differential pressure/high vacuum condition, internal coating protection against corrosion, optional single-point mechanical seal or five-point mechanical seal, labyrinth seal.

Application of Roots Vacuum Pump

Vacculex Roots vacuum pump application in the global manufacturing market: chemical, petrochemical, chemical and pharmaceutical processes, plastics, semiconductors, vacuum furnaces and vacuum melting etc.

Evaporation/Crystallization

Distillation

Solvent recovery

Freeze Drying

Sterilization

Degassing

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

PBAT

PGA

ABS

PS

PC

Degassing

Distillation

Petroleum cracking

Oil and gas recovery

Vapor Recovery

Vacuum degassing

VOC tail gas recovery

Steel degassing

Vacuum furnaces

Vacuum coating

Crystal growth

Deposition

Etching

Wafer movement

Vacuum sintering

Why Choose Vacculex Roots Vacuum Pump

Our Partner

We supply our products to the world’s leading brands in many industries

Roots Vacuum Pump FAQ Guide

1. What is a roots vacuum pump?

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some roots vacuum / booster pumps are equipped with a by-pass valve.

2. Advantages of using a roots vacuum pump

If you’re in the market for a vacuum pump or booster, then you should definitely consider using a Roots vacuum pump / booster. These units offer many benefits that traditional backpumps lack, and they are worth your consideration. Here are some of the main advantages:

– Higher operating efficiencies due to less loss through leakage around seals. This means that fewer resources (mechanical energy or electricity) are needed to achieve the same level of performance.

– Reduced noise levels owing to lack of mechanical contacts between parts. This reduces the amount of noise that is produced by the pumps, making them more comfortable and tolerable for use in residential settings.

– Lower cost owing to simplified design and low running costs (primarily because there is no need for sealants or lubricants). this makes Roots pumps much cheaper than traditional backpumps over all.

3. Disadvantages of roots vacuum pumps

There can be some disadvantages associated with roots vacuums too – mainly related to their unique operating principles which may not be suitable for all applications.

For example, if an incompatible fluid/media mixture is present within a Roots pump’s working chamber then it will cause clogging and failure rather than simply sucking up this unwanted material like traditional back pumps would do. Additionally, when high flow rates must be sustained over extended periods (days or weeks), conditions may arise where vibration induced fatigue damage can occur within root rotors or stator windings

4 .Roots vaccum pump performance characteristics

Roots pumps are great tools for removing surface water, sediment and other pollutants from a drainage system. However, their performance characteristics vary depending on a number of factors, including the number of stages, the unit size, rotation, speed of operation and ambient temperature.

Here are some key points to keep in mind when selecting a roots pump:

-Operating pressure range between atmosphere down to the low 10-2 range.

-Impressively high pumping speed of between 25 and 200m3/hr.

-Good performance when used to pump light gases (such as HCl or nitrogen).

-Very low noise levels (even at high rotational speeds) – even in large systems with many pumps.

-Virtually no vibrations – making them ideal for use in sensitive areas such as hospitals or schools.

5. What are the types of roots vaccum pumps?

Roots vacuum pumps are divided into low vacuum roots vacuum pump with direct air exhaust, medium vacuum roots vacuum pump (mechanical booster pump) and high vacuum roots vacuum pump according to the working pressure range. The largest number of domestic vacuum pumps is root-type vacuums.

- Low-vacuum Roots Vacuum Pump: This type of root vacuums pumps operates in a lower range of pressure than other types. It uses direct air exhaust to help eliminate waste fumes and gases from the system.

- Medium Vacuum Roots Vacuum Pump: This type of root vacuum pumps has a mechanical booster that helps increase working pressure up to a certain level. It is perfect for use in applications with higher pressures or where you need extra suction power.

- High-Vacuum Roots Vacuum Pump: These types of Root Vacs use greater levels of negative atmospheric pressure to provide maximum extraction efficiency from soils and plants. They are ideal for highly specialized applications, such as oil refineries, food handling facilities, pharmaceutical factories, etc

6. What are the applications of roots vaccum pump?

Roots vacuum pump is a widely used device in vacuum metallurgy smelting, degassing, rolling, chemical, food and pharmaceutical industries. Its main applications are as follows:

- – Vacuum Metallurgy Smelting: The roots vacuum pump is often used to reduce the pressure in the furnace during the smelt process. This reduces the amount of slag that forms on the molten metal and results in a more homogeneous product.

- – Degassing: The Roots Vacuum Pump can be used to remove gas or vapor bubbles from liquids or solids using suction power. This is important when manufacturing products such as chemicals, food items or medications.

- – Rolling: By increasing air flow around objects being rolled, the Roots Vacuum Pump can help reduce noise levels and improve production efficiency. It’s also been known to decrease wear on rolling elements due to friction caused by air flowing over them.

- – Chemical Processing: Using high vacuums allows for efficient separation of different compounds by volatilization (vaporization). This technology is often employed in areas such as environmental remediation and drug development .

7. Operating principle of a roots vaccum pump

Roots pumps are one of the most common types of pumps used in industrial and agricultural applications. They employ two counter-rotating interconnected ‘lobed’ rotor units rotating within a stator housing or casing. Gas enters through an inlet flange located perpendicular to the rotating units and is then “isolated” between the rapidly spinning rotors (which are spinning in opposite directions) and the stator. The compressed gas is then expelled via the exhaust port.

There are several advantages to using roots pumps over other types of pumps: they have high efficiency, low noise levels, low power requirements, and long operating lives. Additionally, roots pumps can be used when it’s difficult to access other parts of a plant or equipment because they’re not affected by water buildup or corrosion like electric motors are.

8. How to maintenance roots vacuum pump?

- Always check the oil level position shall be adjusted to conform to requirements of non-compliance when the pump is running to the Roots, and the oil level to mark the center of the oil prevail.

- Drain intervals according to the actual conditions of use and ability meet performance requirements, etc. considered at discretion user’s discretion

- Check for signs of wear and tear – if anything looks wrong, fix it immediately! This includes checking for cracks in rubber seals (and replacing them as needed), cleaning deposits from valves and piston assemblies, cleaning rotary vanes etc., adjusting springs as necessary, etc..

- Regularly run the maintenance program – this will include performing inspections of all Jue rubber seals degree age at time 2000 hours; checking exhaust valve part cracking; clean roots chamber parts such as rotor dust、rotary vanes spray liquid use gasoline straightening dry cloth after cleaned assembly should be gently accidentally touch injuries.

- Bearing lubrication oil should be replaced or supplemented when the level falls below a predetermined point.

- Roots pump tubing and junction should be checked for damage without loosening. Rotate Roots pump to check flexibility of blower vacuum roots

- It is generally recommended that tools should be re-assembled after a test run, in order to empty the running two hours and the second oil change. This is because cleaning the Roots pump would have a certain amount of volatile matter, which would need to be operating normally for it to function properly.

- When starting the motor, it is important to check the pressure gauge and adjust the valve accordingly. This will ensure that the engine stays running smoothly and in proper condition.

- The vacuum booster pump should not be operated if the bearing temperature is above 35C, and the maximum temperature must not exceed 80C.

- Roots installs a hundred hours of labor in the first month to replace oil used every 500 hours. This reduces the amount of oil that needs to be replaced and eliminates any potential messes or spills.

9. Load rating of a roots vaccum pump

Understanding the relationship between power and temperature is important when it comes to pump safety. Rotors can seize if they reach a certain temperature, which is determined by the pressure difference between the pumped gas and the rotors. This pressure difference depends on a number of factors, including pumping speed and gradient. Increases in these variables will increase Δpmax, while decreases will decrease it. It’s important to keep track of all these factors so you can make sure your pumps are running safely.

Continuous operation of a pump must never allow the difference between forevacuum pressure and intake pressure, pV-pa to exceed a certain value depending on the type of pump. Such values are typically in the range between 130 and 50 mbar. However, for brief periods (typically due to special design features, such as gas cooling), this maximum permissible pressure difference may be exceeded. If high pressure differences occur during continuous operation, it is important to take appropriate safety precautions in order to prevent damage or injury.

10. Types of motors used with roots vaccum pumps

Standard flange-mounted motors are a popular choice for applications that require high torque, such as industrial machinery and construction equipment. They are also used in many other applications where durability and ease of use is important, like agricultural machines and vehicles.

The main advantages of using standard flange-mounted motors are their relative simplicity and reliability. These motors are usually protected by two oil sealed radial shaft seals, which help protect the drive shaft from wear and tear. Additionally, these motors can be used with any protection class (voltage or frequency), making them suitable for a wide range of applications.

Integral leak tightness of this version is < 10-4 mbar · l · s-1.

Leak tightness is one of the most important factors when it comes to pumping fluids. If a pump’s seal is not properly sealed, leaks will occur and the pump will eventually fail. Roots pumps are specially designed for applications where high leak tightness requirements are required (10-5 mbar · l · s-1). These pumps have a canned motor which separates the rotor from the stator by a vacuum-tight non-magnetic tube. This prevents wear on seals that might be subject to wear in typical fluid handling applications.

Stay In Touch

Do You Want To Know More About Roots Vacuum Pump

Contact Us For All Your Questions