Blog

What is Screw Vacuum Pumps: Guide to Working Principles and Benefits

Screw vacuum pumps are a type of positive displacement pump that is used to create a vacuum by trapping gas or air molecules in an enclosed chamber. They are widely used in various industrial applications because of their high efficiency, low maintenance, and reliable performance. In this blog, we will explore what screw vacuum pumps are and how they work. We will also discuss the benefits of using these pumps in different applications, such as food processing and metallurgical industries. Additionally, you will find a list of top manufacturers of screw vacuum pumps that you can consider when looking for one that suits your needs. So, if you want to know more about screw vacuum pumps and how they can benefit your business, keep reading!

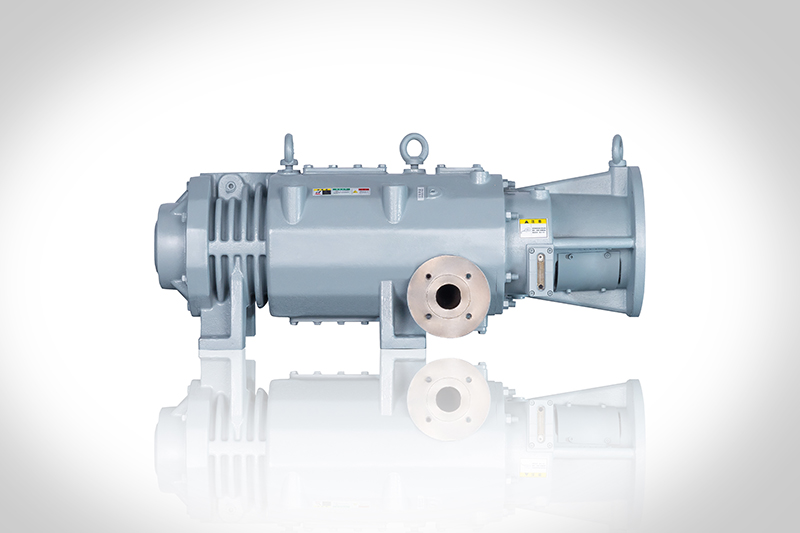

What is Screw Vacuum Pump

Screw vacuum pumps are an essential piece of equipment in many industries, used for creating a vacuum by trapping and transporting gas or vapor. These pumps operate on the principle of two intermeshing screws rotating in opposite directions, allowing them to handle a wide range of gases and vapors. Additionally, screw vacuum pumps offer several benefits such as low noise level, high efficiency, and minimal maintenance requirements. Understanding their working principles and benefits can help businesses make informed decisions when selecting a vacuum pump for their operations.

How Does a Screw Vacuum Pump Work?

A screw vacuum pump is a highly efficient device used to create a vacuum. These pumps operate on a simple principle of intermeshing screws rotating in opposite directions. As the screws rotate, air or gas is trapped and compressed between them, causing the pressure to decrease. The low-pressure area created by this process causes gas to flow towards the outlet port of the pump. Screw vacuum pumps are very versatile as they can handle various gases and liquids, making them an excellent choice for many applications across industries. Their operational efficiency, high reliability, and low maintenance requirements make them a cost-effective solution for businesses looking to optimise their processes.

Dry Screw Vacuum Pump Working Principle

Dry screw vacuum pumps employ two interlocking screws that rotate to reduce the volume of gas or air in a chamber. As they move along the length of the pump, they trap and compress gas or air between them, causing the pressure to decrease. This decrease in pressure creates a vacuum by reducing the volume of gas or air in the chamber. Unlike other types of vacuum pumps, dry screw vacuum pumps are oil-free and require less maintenance. They are widely used in industries such as food processing, pharmaceuticals, and electronics.

Dry Screw Vacuum Pump Operation

Dry screw vacuum pumps have a unique operation that sets them apart from other types of vacuum pumps. They have two rotors that rotate in opposite directions, which creates a vacuum by trapping and compressing gases or air between them. What makes dry screw vacuum pumps stand out is the fact that they don’t come into contact with each other or the casing, which eliminates friction and the need for lubrication. This oil-free system not only saves maintenance costs but also makes them ideal for applications where oil contamination is a concern. Additionally, they are energy-efficient and can handle different gases and vapors, making them suitable for use in various industries such as food processing, pharmaceuticals, and electronics.

Benefits of Screw Vacuum Pumps

Introducing a screw vacuum pump offers numerous benefits, making it an ideal choice for various industries. Unlike other types of vacuum pumps, screw vacuum pumps have a simple design, requiring fewer moving parts leading to low maintenance requirements. The pump operates with high efficiency and consumes less energy than other types of vacuum pumps. It can handle both wet and dry substances without causing any damage and produces lower noise levels during operation. These advantages make screw vacuum pumps suitable for applications in food processing, pharmaceuticals, chemical manufacturing, and more.

Application Benefits

Screw vacuum pumps have a wide range of applications in various industries due to their high efficiency and low maintenance requirements. These pumps are perfect for businesses looking for cost-effective solutions as they offer reliable performance, require minimal maintenance, and have a long lifespan. In addition, the low noise level and reduced vibration make them an excellent choice for creating better working environments. As a result, screw vacuum pumps are widely used in industries such as food processing, pharmaceuticals, and chemical manufacturing.

Easy Maintenance & Quiet Operation

Unlike other vacuum pumps, screw vacuum pumps require minimal maintenance due to their simple design and fewer moving parts. This translates into hassle-free operation and a longer lifespan. In addition, these pumps operate quietly, making them ideal for use in noise-sensitive areas like hospitals and laboratories. The low noise levels also mean that they can be installed in close proximity to work areas without causing disruptions. Thus, screw vacuum pumps offer reliable and efficient performance with low maintenance requirements, making them an attractive option for businesses looking to reduce operating costs.

Wide Operating Range

Screw vacuum pumps offer a wide operating range, making them well-suited for various applications and industries. These pumps can operate at low pressures and handle both dry and wet gases with ease. With high pumping speeds, they can evacuate gases quickly, saving users valuable time. Moreover, screw vacuum pumps are energy-efficient and require lower power consumption than other types of vacuum pumps. Their exceptional performance and versatility make them a reliable choice for applications demanding a wide operating range.

Reliable Performance

Screw vacuum pumps are known for their reliable and consistent performance over a wide range of operating conditions. Their screw design allows for efficient operation with lower energy consumption and reduced maintenance requirements, making them an ideal choice for many industrial vacuum needs. In addition, screw vacuum pumps can handle a variety of gases and vapors, making them suitable for diverse applications in various sectors, such as food, metallurgy, and architecture. With their proven track record of dependable performance, screw vacuum pumps offer a cost-effective solution that delivers quality results every time.

Oil-free Vacuum for Industrial Applications

Screw vacuum pumps are an excellent choice for industrial applications that require an oil-free vacuum. These pumps are designed to handle wet and dry materials, making them versatile and effective. Additionally, they eliminate the risk of oil contamination in sensitive applications like food processing or pharmaceuticals. With minimal maintenance requirements and energy-efficient operation, screw vacuum pumps offer a cost-effective solution for businesses looking to improve their productivity and product quality.

Applications of Screw Vacuum Pumps

Screw vacuum pumps are a versatile solution for many different industrial applications. They are commonly used in the chemical, pharmaceutical, and food processing industries to pump gases and vapors at low pressures. Screw vacuum pumps can handle a wide range of fluids and are easy to maintain, offering high efficiency and reliability in harsh operating conditions. Additionally, they are ideal for use in distillation, evaporation, and drying processes due to their ability to handle both wet and dry materials. Overall, screw vacuum pumps offer a cost-effective solution that can increase productivity while improving product quality.

Food

Screw vacuum pumps are an essential component of the food industry, used for a variety of applications such as packaging, drying, and deaeration. The pumps can handle a wide range of food products, including liquids, powders, and viscous materials. By removing excess air and moisture from the processing environment, screw vacuum pumps help to maintain the quality and freshness of food products. Additionally, they operate quietly with minimal vibration to prevent any contamination during processing. Overall, screw vacuum pumps play a critical role in ensuring the safety and quality of food products.

Vacuum Cooling

Freeze drying

Vacuum packaging

Pneumatic conveying

Metallurgical

The metallurgical industry is one of the primary users of screw vacuum pumps due to their high capacity for handling gases and vapors. These pumps are particularly useful in degassing and vacuum casting applications, where they help remove impurities from molten metal. In addition, screw vacuum pumps have proved reliable for use in heat treatment processes, creating a controlled atmosphere inside furnaces. Overall, the simplicity, durability, and efficiency of screw vacuum pumps make them an essential tool in metallurgical processes.

Architectural

Architectural applications require high-performance vacuum solutions to remove moisture and air from building materials. Screw vacuum pumps are an excellent option for this purpose, as they offer the required level of precision, flexibility, and energy efficiency. These pumps can be customized to fit specific project needs, ensuring a robust and reliable solution for architects and builders. Additionally, using screw vacuum pumps can significantly improve the energy efficiency of buildings by reducing heat loss through insulation. Overall, screw vacuum pumps offer the ideal combination of performance, cost-effectiveness, and customizable features to meet the unique demands of architectural projects.

Top Manufacturers of Screw Vacuum Pumps

When it comes to the top manufacturers of screw vacuum pumps, there are a handful of companies that stand out from the rest. Atlas Copco, for example, is known for its high-quality products that offer exceptional efficiency, low noise and vibration, and minimal maintenance requirements. Gardner Denver is another well-respected manufacturer of screw vacuum pumps, with a focus on providing reliable performance and innovative solutions for a wide range of industries. Pfeiffer Vacuum is also a popular choice among those in need of screw vacuum pumps, offering advanced technologies and exceptional customer support. When considering which manufacturer to choose for your specific needs, be sure to weigh factors such as cost, reliability, and application-specific requirements.

Atlas Copco is a well-known manufacturer of screw vacuum pumps, offering reliable products and excellent customer service for over 100 years. With a range of options to choose from, Atlas Copco’s screw vacuum pumps are designed for various industrial applications such as packaging, food processing, and pharmaceuticals. These pumps offer high efficiency, minimal maintenance requirements, and low noise levels. Additionally, Atlas Copco provides comprehensive support services such as training, maintenance programs and technical assistance to ensure smooth operations for its customers.

When it comes to screw vacuum pumps, Busch is a name that stands out in the industry. With over 50 years of experience, Busch offers a range of high-performance screw vacuum pumps suitable for various applications such as food processing, chemical processing, and pharmaceuticals. These pumps are known for their excellent efficiency, low noise level, and minimal maintenance requirements. Additionally, Busch’s advanced technology ensures stable performance even under extreme conditions. Overall, Busch’s reliable products and exceptional customer service make them one of the top manufacturers in the market.

Gardner Denver is one of the leading manufacturers of screw vacuum pumps, with over 150 years of experience in the industry. The company offers a wide range of models with different capacities and features to meet the specific needs of their customers. Gardner Denver’s screw vacuum pumps are known for their high efficiency and reliability, making them suitable for a wide range of applications. Their products are designed and manufactured using advanced technology and high-quality materials to ensure optimal performance and durability. In addition, to screw vacuum pumps, Gardner Denver also offers a range of other vacuum technologies and solutions.

Leybold is a prominent manufacturer of vacuum technology products, including screw vacuum pumps. Their pumps are known for their reliability, efficiency, and durability. Leybold screw vacuum pumps use two screw rotors to create a vacuum by trapping air between the rotors and the pump housing. The unique construction of this pump allows it to minimize energy consumption while providing consistent performance. They are widely used in various industries such as food processing, chemical, and pharmaceuticals due to their seamless operation and low maintenance requirements. Leybold also offers a range of accessories and services to optimize the performance of their screw vacuum pumps.

Pfeiffer Vacuum is a prominent player in the vacuum technology market, with over 130 years of experience. Their screw vacuum pumps are designed to offer high pumping speeds and low ultimate pressures, making them ideal for a range of applications. These pumps are known for their energy efficiency and low maintenance requirements, providing reliable performance in industries such as semiconductor manufacturing and research & development. Pfeiffer Vacuum also offers customizable solutions to meet specific customer needs, further highlighting their commitment to delivering optimal performance and customer satisfaction.

Vacculex is a leading manufacturer of screw vacuum pumps that are renowned for their innovative design and high-performance capabilities. Unlike conventional screw pumps, Vacculex uses a unique helical rotor design to create a powerful vacuum that handles even the toughest materials with ease. One of the standout features of these pumps is their energy efficiency and quiet operation, making them ideal for both commercial and industrial settings. Vacculex also offers excellent customer service and support to ensure that their customers get the best out of their products.

Contact Our Support Team

Conclusion

Screw vacuum pumps are versatile and efficient machines that are used in a variety of industries. They work on the principle of two interlocking screws, which create a vacuum by reducing the volume of the chamber. The benefits of screw vacuum pumps include easy maintenance, quiet operation, wide operating range, and reliable performance. These features make them ideal for many applications, including food processing, metallurgical processes, and architectural glass production. If you’re looking for top-quality screw vacuum pumps from trusted manufacturers like Vacculex, get in touch with us today to receive customized quotes for your commercial needs.