Blog

The Different Types of Vacuum Pumps Used in Industries

Have you ever wondered what different types of vacuum pumps are used in industries? And how they work? If the answer is yes, then this blog is for you! In this article, we will discuss the different types of vacuum pumps used in different industries and the basic operating principle of each one. We will also provide a list of the pressure ranges of different industrial vacuum systems and two types of industrial vacuum pumps. Finally, we will conclude the article with a short description of the application and quote of Vacculex industrial vacuum pumps in various industries. So read on to learn more!

Table of Contents

What Does An Industrial Vacuum Pump Do

Vacuum pumps are essential in various industrial applications. They’re used to remove air or gas from a confined space, such as an engine, machine, or tank. Different types of vacuum pumps have different benefits and weaknesses; it’s important to choose the right one for your application. For example, a vacuum pump used in manufacturing is usually more powerful and has a longer lifespan than one used in oil and gas production. It’s also important to know the specifications of the vacuum pump you’re considering, so that you can make the right choice. So, the next time you’re shopping for vacuum pumps, be sure to consult the specs sheet and compare different types of vacuum pumps to find the perfect one for your needs.

Basic Operating Principle of an Industrial Vacuum Pump

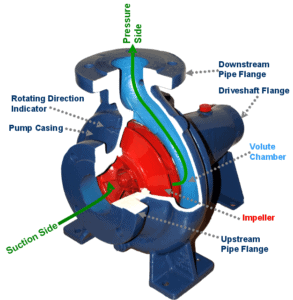

Anyone working in an industrial setting knows the importance of vacuum pumps. These essential machines have a basic operating principle that remains the same, no matter the type of vacuum pump. In fact, vacuum pumps remove gas molecules from the vacuum chamber, which in turn lowers the pressure in the chamber. This makes it easier for the pump to remove additional molecules, and the system as a whole must be able to operate at pressure levels ranging from 1 to 10-6 Torr / 1.3 to 13.3 mBar. Vacuum pumps come in different sizes and shapes, but the basic principle remains the same. So, no matter what type of vacuum pump you’re dealing with, be sure to understand the basics of its operation!

Learn more about how a vacuum pump works by viewing this video:

What is the Pressure Range of an Industrial Vacuum System?

Choosing the right vacuum pump for your industrial vacuum system is crucial. Not only will the pressure range affect the price you pay for the unit, but it will also determine the type of vacuum system you need. There are three pressure ranges used in industrial vacuum systems – low, medium, and high-pressure systems. high-pressure systems are the strongest and fastest, while low-pressure systems are the most common. Knowing the pressure range is essential when choosing a vacuum pump, as it will affect the price you pay for the unit. There are many different types of vacuum pumps used in industries, and each has a different pressure range. The three pressure ranges used in industrial vacuum systems are low, medium, and high-pressure systems. high-pressure systems are the strongest and fastest, while low-pressure systems are the most common.

The industrial vacuum range division as follow:

- Rough/Low vacuum:105-102Pa;

- Fine/Medium vacuum:102-10-1Pa;

- High vacuum:10-1-10-5Pa;

Vacculex products range including screw vacuum pump, roots vacuum pump (also called mechanical vacuum booster), liquid ring vacuum pump etc. Above as example, the working pressure range of different vacuum pumps as follow:

- Screw vacuum pump: 105Pa–5×10-1Pa

- Roots vacuum pump: 103Pa–10-2 Pa

- Liquid ring vacuum pump: 105Pa–3×103 Pa

Two Categories of Industrial Vacuum Pumps

If you’re in the industrial vacuum pump market, you know that there are two main types: wet and dry. Wet industrial vacuum pumps use water to remove the air or gas, while dry industrial vacuum pumps use air. Although the two types of pumps have their advantages and disadvantages, it’s important to choose the right type for your application. To learn more about each type of pump, be sure to read the manufacturer’s specifications. For example, the specifications for a wet industrial vacuum pump might say that it is suitable for applications that require the removal of air or gas in an oil-containing environment. On the other hand, the specifications for a dry industrial vacuum pump might say that it is suitable for applications that require the removal of gas in a water-containing environment. So, the next time you’re in the market for a vacuum pump, be sure to read the specs carefully!

Wet vacuum pumps

Wet vacuum pumps use oil, water or liquid as lubricant or working fluid. While these pumps are a long-lasting and low maintenance option, the working fluid can contaminate the air that’s pumped (or swept) from the chamber, posing health risks to those who are in contact with it. Wet vacuum pumps are used for applications that need a lot of liquid suction, like food processing and beverage making. They come in different types and sizes depending on the application it is being used for.

Dry vacuum pumps

Dry vacuum pumps are an important part of the industrial vacuum system, it is able to discharge the pumped gas directly to the atmosphere, there is no oil or other working medium in the pump chamber, so there is no pollution to the process medium. No pollution, no emission, no waste disposal cost, high ultimate vacuum, long service life and low maintenance cost. Of course, the disadvantage is also obvious, that is, compared to the wet vacuum pump. its price is higher, a high cost of initial investment.

4 Types of Vacuum Pumps Used in Industries

Vacuum pumps are essential in various industrial applications. Choosing the right pump for your business can be a daunting task, but not impossible. To make the process easier, understand the different types of vacuum pumps available and the specific benefits and drawbacks of each. Here are the four types of vacuum pumps: gas transfer pumps, kinetic transfer pumps, positive displacement pumps, and entrapment pumps. Each pump has its own specific advantages and drawbacks, so it’s important to know which one is best for your application. If you have a detailed understanding of the requirements, choosing the right pump will be a breeze.

Gas Transfer Pumps

Gas transfer pumps are used to move gas molecules from one location to another. They work by either transferring the motion of the gas molecules using kinetic action or positive displacement. These pumps can handle large volumes of air with ease and they are very efficient in vacuum transfer. Industries that use these types of pumps include chemical, petroleum, and even food processing plants!

Kinetic Transfer Pumps

Kinetic transfer pumps are used in various industrial applications to move gas or liquid around. These pumps use the energy of motion to create suction and move materials around. They come in different types, such as high speed blades and vapor introduction pumps. Working on the principle of momentum transfer, they use the energy of moving parts to pump fluid or gas. Kinetic transfer pumps are mainly used in industries like oil and gas, mining, power generation etc., where fast movement of materials is required.

Positive Displacement

The positive displacement vacuum pump is a kind of vacuum pump that uses moving parts (rotary or reciprocating parts) to move continuously in the pump chamber, and uses the periodic change of the pump chamber volume to complete the process of suction and exhaust, and the gas is compressed before being discharged. This kind of pump is divided into two types: reciprocating and rotary type.

(1) Reciprocating vacuum pump: It uses the reciprocating motion in the pump chamber to suck in, compress and discharge the gas. It includes diaphragm vacuum pump and piston vacuum pump.

(2) Rotary vacuum pump: It uses the rotor in the pump chamber to make rotating movement to suck in, compress and discharge the gas. It is also one of the most widely used vacuum pumps, including liquid ring pump, oil seal pump, roots pump, screw vacuum pump, scroll pump, claw pump, etc.

Entrapment Pumps

Entrapment pumps are vacuum pumps which capture gas molecules on the surfaces within the vacuum system. They operate at lower flow rates than vacuum pumps such as transfer pumps, and can provide extremely high vacuum (down to 10-12Torr). Capture pumps use cryogenic condensation, ionic reaction, or chemical reaction to capture gas molecules.

Industrial Vacuum Pumps From Vacculex

Vacculex industrial vacuum pumps are the perfect choice for businesses of all types. We offer a variety of pumps that are perfect for a variety of applications, from the screw vacuum pump to the roots vacuum pump and liquid ring vacuum pump. We understand the importance of quality and customer service, which is why we are available 24/7 to help you with any questions or concerns you may have. Our team is passionate with leading vacuum calculation capability, and we are committed to providing the best possible service to our customers. Contact us today to learn more about our industrial vacuum pumps and find the perfect one for your business!

Get all information on Vacculex vacuum pump products now!

Application of Vacculex Industrial Vacuum Pumps

Vacculex industrial vacuum pumps are the perfect choice for any industry! They’re versatile and reliable, and can be used in a variety of applications, such as the food and beverage industry, pharmaceuticals, and chemicals. In fact, the vacculex industrial vacuum pump is an excellent choice for any industry that requires high vacuum levels. Their Evaporation/Crystallization,Distillation,Solvent recovery, and Vacuum coating capabilities make them the perfect choice for a wide range of industrial needs. So what are you waiting for? Add the vacculex industrial vacuum pump to your choice today!

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

Evaporation/Crystallization

Distillation

Solvent recovery

Freeze Drying

Sterilization

Degassing

PBAT

PGA

ABS

PS

PC

Degassing

Frequently Asked Questions

How do I choose the right type of vacuum pump for my application?

When choosing the right vacuum pump for your application, it is important to consider the type of fluid being pumped, the speed and suction requirements, and noise levels. Additionally, it is also important to choose a vacuum pump that is specifically designed for the type of application you are using it in.Some of the most common types od vacuum pumps used in industrial settings including the rotary vane pump, screw vacuum pump, roots pump(negative pressure is vacuum pump, positive pressure is blower), liquid ring vacuum pump,piston pump, claw vacuum pump, sliding valve pump etc.

Which one is better: single stage or multi-stage pumps?

When it comes to vacuum pumps, single stage vacuums tend to be more efficient than multi-stage vacuums. This is because a single stage vacuum pump pulls the dirt and debris together in one place instead of dispersing it throughout the chamber like a multi-stage vacuum pump does. Multi-stage vacuum pumps are better for high volume applications, as the chamber can hold more dirt and debris at one time. However, both single and multi-stage vacuum pumps have their pros and cons. Single stage pumps are better for smaller applications since they’re easier to maneuver and have fewer parts that can malfunction. Multi-stage pumps, on the other hand, are better for high volume applications because they can handle more dirt and debris at one time.

What are the benefits of using a vacuum pump in industries?

There are a number of reasons why vacuum pumps are often used in industrial settings. Let’s take a look:

- By using vacuum pumps, industrialists can achieve high levels of throughput with minimal energy consumption. In some cases, vacuum pumps can work using either compressed air or electricity, which makes them versatile and easy to use.

- They help to reduce the amount of labor required and increase efficiency. As vacuum pumps move large quantities of material at high speeds, they can help to reduce the amount of time it takes to process a certain task.

- Additionally, vacuum pumps can be operated using either compressed air or electricity which makes them versatile and easy to use.

What are some common problems that users experience with vacuum pumps?

Vacuum pumps are one of the most popular types of air compressors and are used in a variety of applications such as industrial, construction, and home maintenance. Unfortunately, vacuum pumps can experience a number of common problems that users have to deal with. Here are the top three:

- Clogged filters: One of the most common problems that users experience with vacuum pumps is clogged filters. This happens when the filter becomes full of debris, dust, or other materials and cannot properly filter the air flow from the pump. Over time, this can cause the pump to break down.

- Inefficient motors: Another common problem with vacuum pumps is that the motors become inefficient over time. This may happen because the motor’s parts wear out or get damaged, affecting its performance. In order to avoid this, it is important to check the filter status and replace it as needed.

- Broken hoses: Finally, make sure that the hoses are not obstructed or kinked – this will cause less suction power and eventually a failure of the pump.

What factors should I consider when choosing a vacuum pump?

When choosing the perfect vacuum pump for your applications, you should first decide the type of liquid being handled. Some pumps are designed specifically for handling liquids while others can handle both liquid and gas. You should also consider the power required and the runtime. For high-volume applications, you will want to opt for a powerful pump with a long runtime. When choosing the right pump for your needs, it is important to factor in the wattage and motor size. Pumps come in different types of applications like industrial, laboratory, pet care, and food service. Therefore, it is important to read up on the different types of pumps available and make a purchase based on the needs you have. Finally, always consider the reviews of vacuum pumps before making your purchase so that you get the best value for your money.

Conclusion

In this blog, you have been introduced to the different types of vacuum pumps used in industries. By understanding the basic operating principle of each pump and the pressure range it can work at, you can make an informed decision about the vacuum pump that is right for your needs. Additionally, the different types of vacuum pumps available are discussed in detail so that you can find the perfect pump for your industrial vacuum system. Make sure to check out the applications of vacculex industrial vacuum pumps to get a better understanding of how they can help your business.

CONTACT VACCULEX VACCUM PUMP