Blog

Vacuum Pump for Industrial Applications: Types and Uses

Industrial vacuum pumps are used in a wide range of industries for various applications. From pharmaceuticals to petroleum, they play a critical role in the functioning of many industrial processes. But what exactly are vacuum pumps, and how do they work? In this blog post, we will delve into the world of industrial vacuum pumps and explore their different types and applications. We will also discuss the benefits of using these pumps and why they are essential for certain industries. Whether you’re an industry professional or just looking to expand your knowledge, this post is for you. So let’s get started!

Understanding Industrial Vacuum Pumps

In various industries, industrial vacuum pumps play a crucial role, from food processing to pharmaceuticals. These pumps are essential in processes such as vacuum packaging, drying, and impregnation of wood. Understanding the types of vacuum pumps is crucial for selecting the right one for specific applications, as they can be used in different pressure ranges, from low vacuum to high vacuum applications. The operating principle of industrial vacuum pumps involves the transfer of momentum between gas molecules. This fundamental understanding helps in optimizing the use of these pumps in a wide variety of industrial applications.

The Operating Principle of Industrial Vacuum Pumps

Industrial vacuum pumps operate by creating a lower pressure in the system, allowing gas transfer to occur from higher to lower pressure regions. The operating principle relies on the transfer of momentum from moving parts to the gas molecules, facilitating the movement of gas molecules in opposite directions for greater efficiency. Positive displacement vacuum pumps, such as rotary vane and liquid ring pumps, utilize specific operating principles based on displacement and compression to ensure specific pressure ranges in industrial applications. Understanding this principle is crucial in selecting the right type of industrial vacuum pump for specific application needs, as it involves the expansion of a cavity to create a vacuum. The static parts of the pump play a vital role in the process, enabling high compression ratios and efficient gas transfer within various industries.

Pressure Ranges in Industrial Vacuum Systems

Industrial vacuum systems encompass a broad pressure range, serving low vacuum applications to high vacuum processes. The diversity of industrial applications necessitates specific pressure maintenance, which is facilitated by a variety of vacuum pumps such as positive displacement and kinetic transfer pumps, including booster pumps. Pressure ranges dictate the type of industrial vacuum pump utilized, directly impacting system performance. From cryogenic condensation to vapor suction, every application demands a unique pressure range, highlighting the critical role of vacuum pumps in ensuring operational efficiency across various industries.

Types of Industrial Vacuum Pumps

Industrial vacuum pumps embrace a wide variety of industrial applications, including positive displacement vacuum pumps such as rotary vane, liquid ring, and screw vacuum pumps. Each type offers specific benefits for different industrial applications, emphasizing the importance of understanding the type of industrial vacuum pump for specific applications. The operating principle, pressure range, and specific application requirements determine the most suitable type of vacuum pump, whether it’s for kinetic transfer pumps or cryogenic condensation. Industries rely on specific types of vacuum pumps, such as compressors, to ensure greater efficiency and application-specific features, such as screw vacuum pumps for improved safety and low noise levels.

Screw Vacuum Pump

Screw vacuum pumps, commonly used across a wide variety of industrial applications, offer specific advantages such as greater efficiency and low vacuum capabilities. These positive displacement vacuum pumps play a pivotal role in specific industrial applications, supporting various pressure ranges. In different industries, screw vacuum pumps provide the necessary pressure range, ensuring efficient gas transfer and compression processes. With low flow rates and high compression ratios, screw vacuum pumps are widely used in industrial vacuum systems, catering to various applications. Understanding the specific application of screw vacuum pumps is essential for selecting the most suitable pump for different industrial processes.

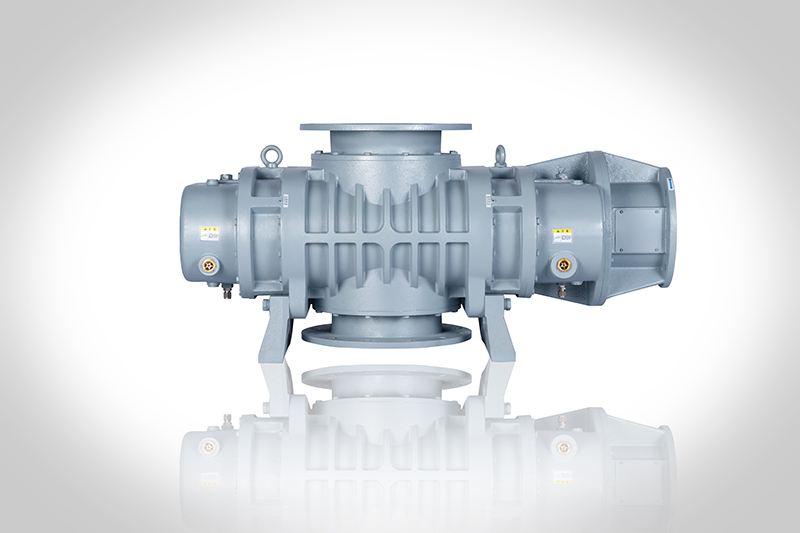

Roots Vacuum Pump

Roots vacuum pumps, often utilized in a wide variety of industrial applications, operate on the principle of positive displacement. This type of industrial vacuum pump offers high compression ratios, catering to the demanding requirements of industrial processes. In roots vacuum pumps, gas molecules are transferred through an entrapment mechanism, ensuring efficient compression and momentum exchange. These pumps provide the necessary pressure range for industrial vacuum systems, supporting gas transfer and compression processes. Due to their ability to maintain high compression ratios, roots vacuum pumps find specific applications in various industries, contributing to greater efficiency and productivity in industrial vacuum applications.

Liquid Ring Vacuum Pump

Liquid ring vacuum pumps are vital for a wide variety of industrial applications, offering specific pressure ranges essential for industrial processes. Their operating principle involves the kinetic transfer of gas molecules through an entrapment mechanism, ensuring specific pressure ranges in industrial systems. In various industries, liquid ring vacuum pumps play a crucial role in maintaining desired pressure ranges, supporting efficient industrial applications. These pumps provide advantages such as low flow rates and high compression ratios, making them suitable for industrial vacuum systems. Industries rely on liquid ring vacuum pumps, including those with a rotating impeller, to maintain specific pressure requirements, ensuring greater efficiency in industrial processes.

Benefits of Using Industrial Vacuum Pumps

Using industrial vacuum pumps ensures efficiency, cost savings, and optimized performance for a wide variety of industrial applications, from packaging to gas transfer. These positive displacement vacuum pumps offer specific advantages, including low flow rates, high compression ratios, and low vacuum capabilities, supporting the efficiency of industrial processes across various industries. Additionally, industrial vacuum pumps provide the necessary pressure range, ensuring the efficient operation of vacuum systems and supporting the diverse industrial applications. The benefits of using these pumps extend to different industries, offering specific advantages such as gas transfer, compression, and pressure maintenance, thereby contributing to greater efficiency and cost savings across different industrial processes.

Cost Savings

Industrial vacuum pumps contribute to cost savings by enhancing process efficiency, minimizing maintenance requirements, and reducing energy consumption in a wide variety of industrial applications. They ensure efficient gas transfer, compression, and pressure maintenance, resulting in tangible cost savings across different industries. With specific advantages like low flow rates, high compression ratios, and low vacuum capabilities, industrial vacuum pumps offer significant cost savings for various applications. These cost savings extend to different industries, supporting efficient processes and enhancing overall industrial performance.

Enhanced Productivity

In various industrial applications, industrial vacuum pumps play a crucial role in enhancing productivity. These pumps efficiently eliminate unwanted materials, leading to increased productivity and quicker material handling, which ultimately improves overall operational efficiency. Moreover, industrial vacuum pumps are essential for maintaining high production rates and the efficiency of various industrial processes, supporting a wide variety of industrial applications. Their positive displacement enables them to contribute to greater efficiency in specific applications, making them indispensable for ensuring optimal performance across various industries.

Improved Safety

Industrial vacuum pumps play a pivotal role in enhancing safety within industrial environments. Their contribution to the safe and efficient handling of hazardous materials is significant. By aiding in the containment of harmful substances, these pumps ensure a secure working environment, minimizing the risk of exposure to potentially dangerous materials. Their vital role in preventing accidents and ensuring workplace safety cannot be overstated. With their ability to contribute to improved safety standards, industrial vacuum pumps are essential for maintaining a secure and risk-free industrial workspace.

Low Noise Levels

Industrial vacuum pumps are meticulously engineered to operate at minimal noise levels, ensuring a quiet and conducive work environment. These pumps offer efficient performance while minimizing noise emissions, contributing to a more comfortable workplace for employees. By reducing noise pollution in industrial settings, vacuum pumps play a significant role in creating a peaceful work atmosphere. Their quiet operation enables uninterrupted workflow, enhancing productivity in various industrial applications. With a focus on low noise levels, industrial vacuum pumps prioritize employee comfort and safety, making them an essential component in a wide variety of industrial applications.

Applications of Industrial Vacuum Pumps

Industrial vacuum pumps play a vital role in a wide variety of industrial applications, including the pharmaceutical, chemical, and petroleum industries. In the pharmaceutical industry, these pumps are essential for the efficient and safe processing of pharmaceutical products. Similarly, the chemical industry extensively utilizes industrial vacuum pumps for various processes, benefiting from their specific applications. Moreover, industrial vacuum pumps play a crucial role in the operations of the petroleum industry, aiding in the effective extraction and processing of petroleum products. Across these different industries, the positive displacement vacuum pumps offer greater efficiency, making them indispensable for various industrial applications.

Pharmaceutical

The pharmaceutical industry relies heavily on industrial vacuum pumps for the safe and efficient production of drugs and medications. These pumps play a crucial role in maintaining the quality and integrity of pharmaceutical products, ensuring compliance with manufacturing processes. Utilized to achieve low pressure, they contribute to the safe processing of pharmaceutical products within stainless steel and vacuum chambers. In the pharmaceutical industry, rotary vane pumps, piston pumps, and entrapment pumps are commonly used to achieve lower flow rates and efficient momentum exchange.

Evaporation/Crystallization

Distillation

Solvent recovery

Freeze Drying

Sterilization

Degassing

Chemical

In chemical processing applications, industrial vacuum pumps play a crucial role, facilitating the safe and efficient handling of chemical substances. They contribute to the removal of unwanted materials and by-products, optimizing and executing chemical procedures with precision. Moreover, these pumps are essential for maintaining the integrity and quality of chemical products across a wide variety of industrial applications. Their positive displacement enables them to operate in specific chemical applications, making them vital for the industry. The vacuum pumps are integral to ensuring safety and efficiency in chemical processes, catering to the unique requirements of the chemical industry without compromising on quality.

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

Petroleum

Industrial vacuum pumps are vital for the efficient processing of petroleum products in various industries. They play a crucial role in the extraction, refining, and distribution of petroleum, aiding in the safe and effective handling of various petroleum-based materials. These pumps contribute significantly to the operational efficiency of petroleum processes, ensuring smooth and reliable operation. With a wide variety of industrial applications, industrial vacuum pumps are instrumental in maintaining the integrity and quality of petroleum products. Their positive displacement and high compression ratios enable them to handle the specific requirements of the petroleum industry. By leveraging different types of pumps, the petroleum sector benefits from greater efficiency and productivity, meeting the diverse needs of this dynamic industry.

Distillation

Petroleum cracking

Oil and gas recovery

Vapor Recovery

Vacuum degassing

VOC tail gas recovery

Why are Vacuum Pumps Essential in Industries?

Vacuum pumps have become an indispensable part of various industries owing to their ability to provide the required pressure for diverse processes. In industrial applications such as packaging, drying, and gas transfer, vacuum pumps play a vital role in creating a vacuum environment through the use of coating technology. By maintaining specific pressure ranges, these pumps ensure optimal efficiency and support critical industrial processes. For instance, in the manufacturing industry, vacuum pumps are used for creating vacuum conditions during the production process. They are also used in laboratories for removing air from containers and creating a vacuum environment. Vacuum pumps come in different types, including rotary vane pumps, diaphragm pumps, and liquid ring pumps, among others. Each type has its unique advantages and disadvantages that make them suitable for specific applications. It is essential to select the right type of vacuum pump that best suits an application’s requirements to achieve optimal performance.

Conclusion

In conclusion, industrial vacuum pumps play a crucial role in various industries, providing numerous benefits such as cost savings, enhanced productivity, improved safety, and low noise levels. The different types of industrial vacuum pumps, including roots vacuum pumps, liquid ring vacuum pumps, and screw vacuum pumps, cater to different applications and pressure ranges in industrial vacuum systems. These pumps find applications in industries such as pharmaceutical, chemical, and petroleum, where creating and maintaining vacuum conditions is essential for various processes. If you are in need of industrial vacuum pumps for your business, don’t hesitate to reach out for quotes and explore the options that best suit your requirements.

Contact Our Support Team