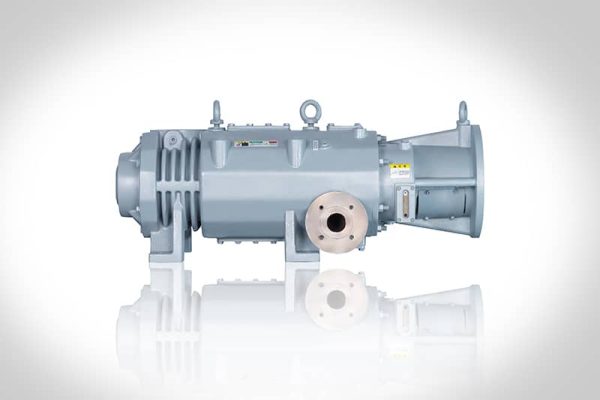

Screw Vacuum Pump

Dry screw vacuum pump, is the the pumping equipment that use a pair of screws, to perform synchronous high-speed reverse rotation in the pump casing to generate suction and exhaust.

Vacculex

About Screw Vacuum Pump

The two screws of screw vacuum pump are corrected by fine dynamic balance, supported by bearings, installed in the pump casing, there is a certain gap between the screws, so when the pump working, no friction between each other, smooth operation, low noise, the working chamber without lubricating oil, therefore, the dry screw vacuum pump can pump out the gas containing a lot of vapor and a small amount of dust, its ultimate vacuum can reach 10 pa, with advantage of low power consumption, energy saving, maintenance-free, etc. It is an updated product of the traditional vacuum pump, representing the highest level of the vacuum industry at present, and is the direction of the vacuum industry development.

Find out How Our Screw Vacuum Pump Work

Similar to screw compressor, the working process of screw dry vacuum pump can be divided into three processes: suction, compression and exhaust. As the rotor rotates, each pair of mutually meshed teeth completes the same working cycle one after another, and now one pair of teeth is used to explain.

– Suction process

The positive rotor rotates in the counterclockwise direction and the negative screw rotates in the clockwise direction. The upper rotor end face is the suction section and the lower end face is the exhaust section.

– Compression process

The rotor end face is the exhaust end face. Here, the positive rotor rotates in the clockwise direction and the negative rotates in the counterclockwise direction. The upper rotor end face is the suction section, and the lower end face is the exhaust section.

– Exhaust process

Screw vacuum pump exhaust process, the volume between the teeth and the exhaust orifice connected, that is, the exhaust process begins. As the volume between the teeth continues to shrink, the gas with exhaust pressure is gradually discharged through the exhaust orifice.

Select Our Screw Vacuum Pump

Variable pitch, high ultimate pressure, large pumping capacity, fast exhaust, energy saving, low medium gas condensation, low exhaust temperature, no carbonization, anti-stuck, long life, dry type without oil and water, corrosion resistant coating treatment for fluid contact part.

Application of Screw Vacuum Pump

Vacculex screw vacuum pump application in the global manufacturing market: chemical, petrochemical, chemical and pharmaceutical processes, plastics, semiconductors, vacuum furnaces and vacuum melting etc.

Evaporation/Crystallization

Distillation

Solvent recovery

Freeze Drying

Sterilization

Degassing

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

PBAT

PGA

ABS

PS

PC

Degassing

Distillation

Petroleum cracking

Oil and gas recovery

Vapor Recovery

Vacuum degassing

VOC tail gas recovery

Steel degassing

Vacuum furnaces

Vacuum coating

Crystal growth

Deposition

Etching

Wafer movement

Vacuum sintering

Why Choose Vacculex Screw Vacuum Pump

Our Partner

We supply our products to the world’s leading brands in many industries

Screw Vacuum Pump FAQ Guide

1.What kind of situation should consider using screw vacuum pumps?

Dry screw pumps are a popular choice for small- to medium-sized applications because they offer several benefits over traditional wet pump solutions. Most notably, dry screw pumps do not require any operating fluids or lubrication, which makes them much less expensive to operate and maintain.

Another benefit of the dry design is that there is no vacuum in the system – this eliminates the need for a compression chamber. This means that dry screw pumps can be operationally simpler than Wet Pump systems, and they tend to have higher flow rates at lower pressures due to their greater efficiency.

One downside of dry screws is that they experience wear more rapidly than wet screws due to their lack of lubrication. In order for these pumps to function optimally, it’s important periodically apply a quality oil or grease throughout the entire machine while it’s running

2.What is dry screw vacuum pump?

A dry screw vacuum pump is a type of rotary positive displacement pump that operates without the need for oil or other types of lubricants. It consists of two interlocking screws (there is small clearance between two screws) with helical grooves that rotate inside a casing, trapping gas molecules and conveying them along the casing until they are discharged at the exhaust port.

The absence of oil eliminates the risk of contamination, and also reduces maintenance and operating costs compared to traditional oil-sealed vacuum pumps. With advantage of no waste liquid/lubricant disposal expenses, environmentally friendly emissions, increased efficiency and energy saving.

Dry screw vacuum pumps have applications in various industries, including semiconductor manufacturing, chemical processing, industrial vacuum, healthcare, food and aerospace etc.

3. What are the types of dry screw vacuum pump?

Basically, there are three common structural forms of screw vacuum pumps: equidistance pitch screw, variable pitch screw, special-shaped variable-pitch screw. Vacculex screw vacuum pump using special-shaped variable-pitch screw design, comparing equidistance pitch screw and normal variable pitch screw designs, Vacculex’s dry screw pump have advantages as follow:

- Significantly reduce exhaust gas temperature.

- Significantly reduce the surface temperature of theexhaust port.

- Significantly reduce power consumption.

- Higher pumping efficiency at the high vacuum end. Better gas compression efficiency.

4. Difference between Dry Screw vacuum pump and Liquid Ring vacuum pump

Principle of Operation

The liquid ring vacuum pump is a reliable and efficient tool for performing various operations, such as sampling, desalination, and oilfield production. Its rotating multi-blade impeller creates a centrifugal force that pulls the sealing liquid up into the housing. This causes a liquid ring to form around the impeller, which creates the necessary vacuum for operation.

Dry screw vacuum pumps are a type of rotary pump that generate vacuum through the rotation of two screw rotors arranged parallel to each other. The rotor’s movement decreases the volume of the trapped gas and results in the compression of the gas, moving it out through the exhaust. No lubrication is required in the compression chamber as the rotors do not contact each other during the compression process. As a result, this is referred to as dry technology. Dry screw vacuum pumps have many advantages over traditional wet-style rotary vacuum pumps, including:

- No working fluid

- No contamination to process media

- No contamination, no emissions, no waste disposal costs

- More stable vacuum level, wider application range

- Higher ultimate vacuum degree

- Longer service life

- Low maintenance costs

Energy Consumption

Liquid Ring vacuum pumps consume significant amounts of energy during operation due to the need to maintain a large body of circulating liquid. Dry Screw vacuum pumps require less maintenance than their liquid ring counterparts since there is no need to constantly replace the operating medium (liquid rings), reducing energy consumption. And screw vaccum pump have 90% less water required for cooling than liquid ring pumps

Maintenance Requirements

Maintenance requirements for Dry Screw vacuum pumps are lower because they don’t have liquids to be added or replaced regularly compared to the regular replacement schedules that come with liquid ring technology.

Efficiency/Performance

Screw vacuum pump is known for its high volumetric efficiency, meaning they can produce a higher flow rate at low pressures while using less energy. It also have low maintenance costs due to fewer moving parts and no need for lubrication. Liquid ring vacuum pumps have lower volumetric efficiency than screw vacuum pumps, meaning they may consume more energy over time.

In addition to efficiency, the ultimate vacuum of dry screw vacuum pumps is much higher than the ultimate vacuum of liquid ring pumps. And the ultimate vacuum of liquid ring vacuum pump is determined by its saturation vapor pressure.

Application

Dry Screw vacuum pumps are suitable for industries requiring high-speed evacuation rates, low vibration levels or strict pollutant discharge requirements, also suitable for which fluid can contaminate the vacuum system. Meanwhile, Liquid Ring vacuum pumps work widely in chemical processes, pharmaceuticals, and many others.

5.Key characteristics of vacculex dry screw vacuum pump?

(1). Special-shaped variable-pitch screw design.

(2). Spiral jacket cooling structure, effectively reduce the temperature of the pump chamber.

(3). Lip seal + mechanical seal + gas purge structure, effectively prevent leakage

(4). Max.allowable exhaust temperature: 150℃(VSP150/VSP300/VSP400/VSP800)

Max.allowable exhaust temperature: 150℃(VSP1500/VSP3000).

(5). Typical noise level(without silencer): < 81(Max. 85) @ 60Hz

< 77(Max. 82) @ 50Hz

(6). Typical vibration: Below 4.5mm/sec

(7). Dry screw vacuum pump material:

- Casing : Ductile Iron (QT450).

- Screw: Ductile Iron (QT500)

- EndCover:Ductile Iron(QT450)

- . Internal fluid contacting parts coating: Ni-p or PFA optional choice.

6. Where can dry screw vacuum pump be used?

Dry screw vacuum pumps can be used in a variety of industries and applications, including but not limited to:

- Semiconductor manufacturing

- Food processing

- Pharmaceutical production

- Chemical and petrochemical industries

- Vacuum distillation

- Pulp and paper industry

- Medical equipment

- Surface coating

- Metallurgical processes

- Solar panel manufacturing

- Lithium material production

Overall, the dry screw vacuum pump is a popular choice for applications that require high performance, energy efficiency, and low maintenance.

7.What are the advantages and disadvantages of dry screw vacuum pump?

- Clean, oil-free and Robust

- High tolerance to water vapor and dust/particles

- No contamination to the processed medium, no emissions, no waste disposal costs

- Frictionless rotation – eliminates rotor wear

- High pumping efficiency, highgas compression efficiency

- High pumping speed

- Long service intervals, comparatively low maintenance cost and operational cost

- High energy efficiency through frequency converter operation, can be optimized for process requirements

- Lower power consumption

8.What are the disadvantages of dry screw vacuum pump?

- Dry screw vacuum pump can deal with pumped medium with water, but if the water percentage in the pumped medium is very large, screw vacuum pump would not be able to do it.

- Its structure&design characteristics decide that it is not able to achieve small pumping speed below 50 m³/h and large pumping speed above 3000 m³/h, so what we can see in the global market all the screw vacuum pumps are within this range.

- Difficult process of workingand complicated design constructure decide its price is comparatively high. Vacculex provides clients a choice of balance between high quality&competitive price.

Stay In Touch

Do You Want To Know More About Screw Vacuum Pump

Contact Us For All Your Questions