Knowledge

Application of Vacuum Freeze Drying Technology in Food

With the continuous improvement of living standards, people put forward higher requirements for food quality, vacuum freeze-drying technology was born, vacuum freeze-drying technology can turn fruits and vegetables into dehydrated vegetables and freeze-dried fruits and vegetables, remove the water in fruits and vegetables, but still retain the chlorophyll, vitamins and other nutrients in fruits and vegetables, at room temperature with a longer shelf life, eat only when the fruits and vegetables can be soaked in water to recover, thus retaining the original color, taste, nutrition to a greater extent.

Vacuum freeze drying is the technology to freeze the material below the eutectic point temperature first, so that the water becomes solid ice, and then under the appropriate vacuum, so that the ice directly sublimates to water vapor, and then use the water vapor condenser in the vacuum system to condense the water vapor, so as to obtain the drying.

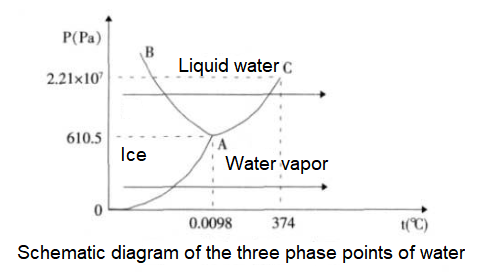

When the pressure is higher than 610.5pa, the water turns into solid ice, and the water is heated and warmed up under equal pressure as a result of passing through the liquid state before turning into the gas state.

When the pressure is lower than 610.5pa, water is heated and warmed up from solid ice directly by solid ice to gaseous state.

Freeze-dried food must first be pre-frozen below its crystallization temperature, and after pre-frozen, the ice must be removed from the food by drying, but ordinary drying methods are usually carried out at room temperature, and the products obtained by drying generally have the problems of volume reduction and texture hardening, and most of the volatile components will be lost, and some heat-sensitive substances are denatured and inactivated, and some substances are even oxidized, so in the drying process Therefore, in the drying process, vacuum cold junction is necessary, and the pre-frozen food shall be dried by vacuum sublimation quickly, and the second analysis and drying shall be carried out by vacuum pump to reduce the air pressure in the drying room to exclude about 3% of solid water in the remaining food, and the freeze-dried food shall be weighed and vacuum packed again.

Features of freeze-dried foods:

- Dehydration is more thorough, reducing weight and facilitating transportation

- Drying can eliminate water, so that the dried product can be preserved for a long time without deterioration.

- After drying, it is spongy, dissolves after adding water, and immediately recovers its original properties.