Blog

Screw Blower vs Roots Blower: Which is Better?

When it comes to selecting a blower for your specific application, it’s important to understand the differences between various types of blowers. Two popular options are screw blowers and roots blowers. Both of these blowers play a crucial role in industries that require compressed air, such as wastewater treatment, chemical industry,power plant and more. In this blog post, we will dive into the functionality, advantages, and disadvantages of screw blowers vs roots blowers, and help you determine which one might be better suited for your needs.

Understanding Blowers: An Overview

Before we delve into the specifics of screw blowers and roots blowers, let’s start with a general understanding of blowers. Blowers are positive displacement machines that compress air, which can then be used for various applications. They are essentially air pumps that deliver a specific volume of air at a given pressure. The volume of air displaced by a blower is a crucial factor in its performance, as it directly affects the efficiency of the system. Now, let’s explore the functionality and key components of blowers in more detail.

The Functionality of Blowers

Blowers, as mentioned earlier, work by moving air or gas through mechanical components, creating positive displacement to ensure a consistent flow of air. They are crucial in different industries, including wastewater treatment, power plant, chemical industry, and aeration etc., where a specific volume of air needs to be compressed. The compressed air generated by blowers plays a significant role in a variety of applications, from chemical industry to facilitating aeration in wastewater treatment plants. Therefore, understanding blower functionality is key to optimizing their performance in these diverse industries.

Blowers differ from fans in that fans simply move air, while blowers compress air, providing a continuous and controlled flow. The volume of air displacement, measured in cubic feet per minute (CFM), determines the capacity of a blower system. Higher CFM ratings indicate a greater volume of air being compressed, which can have a direct impact on the efficiency and effectiveness of a blower.

Key Components of Blowers

Blowers consist of several key components that work together to compress air effectively. These include lobes, rotors, pulleys, discharge outlets, and compression chambers. The lobes, typically made of high-strength steel or cast iron, are the heart of the blower. They rotate within the blower housing, creating a positive displacement of air. The rotation of the lobes is driven by a pulley system, which is typically connected to an external power source, such as an electric motor or an engine.

The compression chamber, located between the lobes, facilitates the compression of air as the lobes rotate. It is designed to minimize air leakage and maximize the efficiency of the compression process. Finally, the discharge outlet, positioned at the end of the compression chamber, allows the compressed air to exit the blower and be directed to the desired application.

Understanding these key components helps in diagnosing and fixing blower issues. Regular maintenance and proper alignment of these parts ensure long-term operational efficiency. Additionally, the design and configuration of these components can have a significant impact on the overall performance of a blower system, making it crucial to consider them when selecting a blower for a specific application.

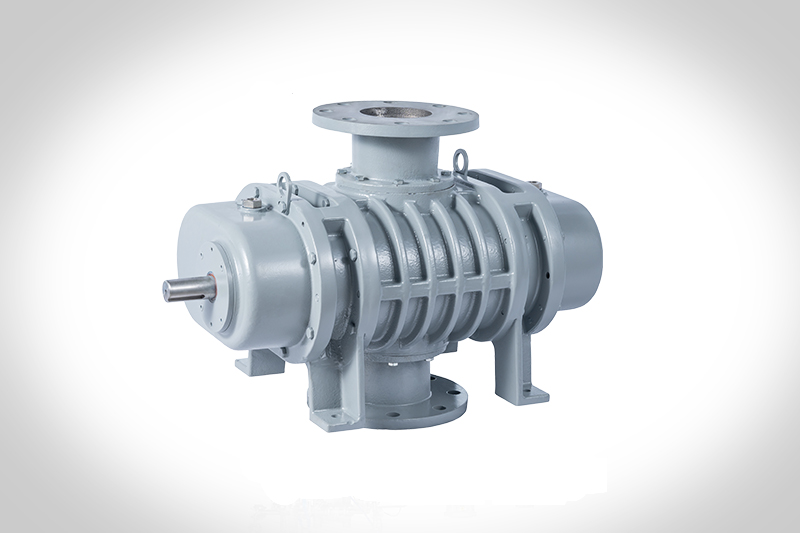

Exploring the Roots Blower

Now that we have a general understanding of blowers, let’s explore one type in particular, the roots blower. Also known as a roots supercharger, roots blower, or roots brothers blower, this type of blower has been widely used in various industries for many years. Its unique design and functionality make it a popular choice for applications that require a steady flow of compressed air. In the following sections, we will delve into the specifics of roots blowers, starting with their basic definition and working principle.

What is Roots Blower

A roots blower is a type of positive displacement blower that utilizes intermeshing lobes to move air. It was invented by the roots brothers in the late 19th century and has since been widely used in various industries, including automotive, wastewater treatment, and more. Roots blowers are often used as superchargers in engines, where a steady supply of compressed air is necessary to increase horsepower and torque.

The basic operation of roots blowers involves air being trapped in the space between the intermeshing lobes and pushed in a continuous, non-pulsating manner. This design ensures a steady flow of compressed air, making roots blowers ideal for applications requiring a consistent volume of air, such as pneumatic conveying or aeration in wastewater treatment plants.

The Working Principle of Roots Blowers

The working principle of roots blowers relies on the displacement of air by the movement of the lobes. As the lobes rotate, air is drawn into the blower through the intake, filling the spaces between the lobes. The rotating lobes then carry air to the discharge port, where it is released into the compression chamber. Due to the design of roots blowers, the air compression process is non-contacting, resulting in a pulsation-free airflow.

One of the key advantages of roots blowers is their efficiency at low RPMs, making them a suitable option in applications where a steady flow of compressed air is required. The simple mechanism of roots blowers ensures continuous and reliable air delivery, contributing to their widespread use in various industries.

Advantages and Disadvantages of Roots Blower

Now that we have a clear understanding of the roots blower, let’s examine some of its advantages and disadvantages. Like any technology, roots blowers have their strengths and weaknesses, which should be taken into consideration when selecting a blower for a specific application. Understanding these pros and cons will help you make an informed decision.

Benefits of Roots Blowers

Roots blowers provide a constant and pulsation-free airflow, making them ideal for applications requiring a steady volume of air.These blowers are known for their robustness and long operational lifespan, providing reliable performance over time.The simple design of roots blowers results in minimal maintenance requirements, reducing downtime and increasing productivity.

Some other benefits of roots blowers include:

- Less heat generation compared to other types of blowers

- Ability to compress a large amount of air, making them suitable for pneumatic conveying and other high-demand applications

- These advantages make roots blowers a popular choice in various industries, where a continuous, reliable supply of compressed air is required.

Limitations of Roots Blowers

Despite their many benefits, roots blowers also have limitations that should be considered: Lower efficiency compared to other blower types, resulting in less overall energy efficiency.Heat buildup can be a problem in roots blowers due to their design, which can impact performance and durability.Limited boost levels, making roots blowers less suitable for applications requiring high compression ratios.

Other limitations of roots blowers include:

- Speed limitations, as they may not perform optimally at high RPMs

- Noise levels, which can be higher compared to other blower types

- Understanding the limitations of roots blowers is crucial for selecting the right blower type for a specific application, considering factors such as efficiency, boost levels, and heat generation.

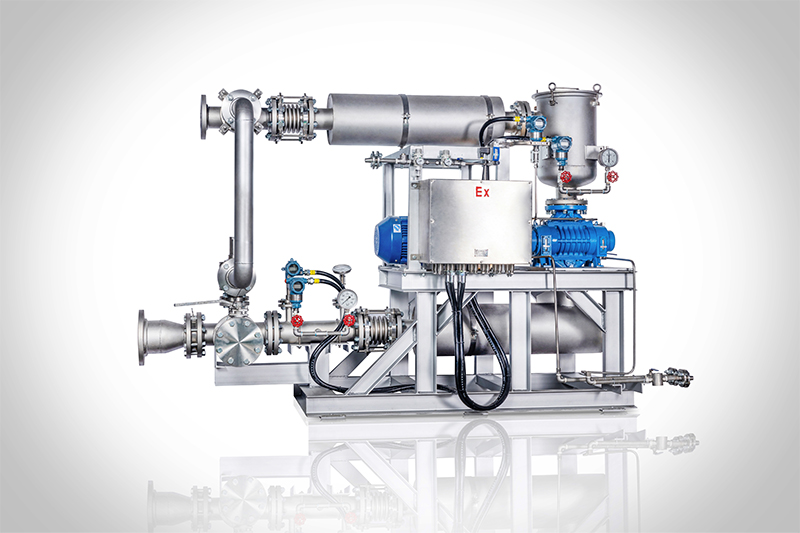

Delving into the Screw Blower

Now let’s shift our focus to screw blowers, which are another type of blower commonly used in various applications. Screw blowers, also known as screw type blowers, have gained popularity due to their efficiency, reliability, and performance advantages over roots blowers. In the following sections, we will explore the specifics of screw blowers, starting with their basic definition and functionality.

What is Screw Blowers

Screw blowers utilize a pair of interlocking helical rotors to compress air efficiently. They ensure a seamless and uninterrupted airflow of compressed air, showcasing reliability in diverse applications. Compared to Roots blowers, screw blowers outperform with their capacity to deliver a greater volume of compressed air.

How Does a Screw Blower Work?

The operation of screw blowers revolves around the compression process generated by the rotation of the helical rotors. As the rotors rotate, air is drawn into the intake port, filling the spaces between the rotor lobes. The rotation of the rotors compresses the air by reducing the volume between the rotor lobes, resulting in increased pressure. This compression process is continuous and pulse-free, providing a smooth and consistent flow of compressed air.

Screw blowers are characterized by minimal heat generation during operation, which is a significant advantage over other blower types. The design of screw blowers allows for efficient air compression, resulting in improved performance and energy efficiency.

Advantages and Disadvantages of Screw Blower

While screw blowers offer several advantages, it’s essential to consider both their positive aspects and drawbacks. Understanding the pros and cons of screw blowers will help you make an informed decision when selecting a blower for your specific application.

Positive Aspects of Screw Blowers

The positive displacement of screw blowers ensures reliable operation and a consistent volume of compressed air supply.Screw blowers are capable of handling varying boost levels effectively, making them suitable for applications with different compression requirements.They are known for their high volume and efficient compression of air, making them ideal for applications that demand a continuous flow of compressed air.

Some other benefits of screw blowers include:

- High efficiency, resulting in cost savings over the long term

- Less heat generation compared to other blower types, contributing to overall energy efficiency

- Used in wastewater treatment plants due to their efficiency in aeration processes

- These advantages make screw blowers a preferred choice in industries that rely on a reliable, efficient, and continuous supply of compressed air.

Drawbacks of Screw Blowers

Despite their positive aspects, screw blowers also have certain limitations that should be considered when selecting a blower type. These include:

Higher upfront cost compared to roots blowers and other blower types, which may require a larger initial investment.Additional maintenance and repair costs, although they are generally lower compared to roots blowers. In some cases, screw blowers may require specialized expertise for servicing or repair, adding to the overall cost.

Other potential drawbacks of screw blowers include:

- Noise levels, which can be a concern depending on the application and operational environment.

- Installation considerations, as screw blowers may require specific setup requirements.

- It is important to carefully evaluate these limitations when considering screw blowers for a specific application, ensuring a thorough assessment of the benefits, drawbacks, and overall suitability for the intended purpose.

Comparative Analysis: Screw Blower vs Roots Blower

Now, let’s compare screw blowers and roots blowers, examining their performance, efficiency, maintenance, and cost, to determine which might be the better option for your needs.

1.Structure difference

Roots blowers are produced by two synchronized rotating, non-contact impellers that physically force the gas through the space in front of the blades, creating a positive pressure. The screw blower is driven to rotate by two helically meshing screws, with air moving in and out of the only compression chamber, and then the gas is discharged.

2.Working process difference

Roots blower two impeller clearance is very small, the gas from the suction port into the Roots blower, constantly blocked by the impeller, forced to move to the static pressure area, so as to achieve the purpose of compression of air. Screw blower is in the two rotating screw engagement process, the gas with the screw rotation and is driven and compressed, in a fixed volume to complete the gas compression and transportation.

3.Different scope of application

As the Roots blower adopts non-contact structural design, it is suitable for occasions with smaller gas volume and higher pressure. Screw blowers are suitable for areas with larger gas volumes and lower pressure ranges, and are usually used for pressurizing and conveying liquid and gas pressure.

4.Maintenance costs difference

Due to the simple structure of the working principle of the Roots blower, long service life, so the maintenance cost of the Roots blower is relatively low, while the screw blower due to the complex structure, the need for regular inspection and maintenance, maintenance costs are relatively high maintenance.

Choosing the Right Blower for Your Needs

Choosing the right blower for your specific needs requires a thorough understanding of the type of supercharger or air compressor that best suits your application. Factors such as efficiency, boost levels, volume of air, and type of supercharger need to be considered. Both roots blowers and screw blowers have their advantages and are suitable for different applications.

If reliability, simplicity, and a steady flow of compressed air are important for your application, a roots blower may be the best way to go. Roots blowers are known for their long operational lifespan, low maintenance requirements, and availability in varying sizes, making them suitable for a wide range of applications. They are commonly used in chemical industry, wasterwater treatment etc. application, where a constant volume of compressed air is crucial for optimal engine performance.

On the other hand, if efficiency, low heat generation, and a high volume of compressed air are of utmost importance, a screw blower might be the better option. They excel in applications that require continuous and efficient compression, such as wastewater treatment plants or industrial air compression systems.

By carefully evaluating your specific needs, considering the talking points mentioned earlier, and understanding the unique features of screw blowers and roots blowers, you can make an informed decision when selecting a blower for your application.

Conclusion

In conclusion, both the Roots blower and the Screw blower have their own set of advantages and disadvantages. The choice between the two ultimately depends on your specific requirements and preferences. If you prioritize cost-effectiveness and simplicity in design, the Roots blower might be the more suitable choice. It is important to carefully consider factors such as performance, efficiency, maintenance, and cost before making a decision. If you need further assistance or want to get quotes for your specific needs, feel free to reach out to us.