Blog

Mastering Positive Displacement Pump Applications

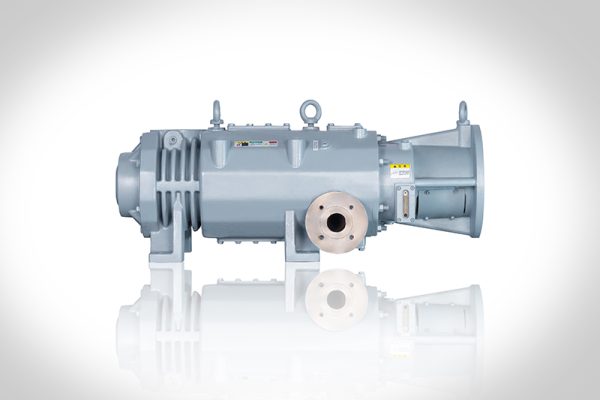

Positive displacement pumps play a crucial role in various industries, providing efficient and reliable fluid transfer solutions. These pumps, with their unique design and working principle, offer numerous advantages over other types of pumps. Understanding the positive displacement pump applications can help industries make informed decisions when it comes to selecting the right pump for their operations.

Understanding Positive Displacement Pumps

Positive displacement pumps are commonly used in industries where precision and controlled fluid transfer are essential. Unlike centrifugal pumps that rely on centrifugal force, positive displacement pumps trap and move a specific amount of fluid with each cycle. This displacement action ensures a constant flow rate, making positive displacement pumps ideal for applications requiring precise fluid transfer. There are different types of positive displacement pumps, each with its own pump designs and mechanisms.

The Working Principle of Positive Displacement Pumps

Positive displacement pumps work based on the principle of positive displacement, wherein they displace a fixed volume of fluid with each cycle. This results in a constant flow rate, irrespective of pressure fluctuations or viscosity variations. The pump’s discharge rate is directly proportional to its speed, ensuring accurate flow control. Positive displacement pumps are highly efficient for moving viscous liquids, as they can generate high pressure and handle high viscosity fluids effectively. These pumps also excel at handling sensitive or thin liquids, making them suitable for applications that require precise flow rates.

The Different Types of Positive Displacement Pumps

There are several types of positive displacement pumps, each designed to cater to specific application requirements. These include:

- Rotary positive displacement pumps: These pumps, such as gear pumps and lobe pumps, work well for both low and high viscosity fluids. They provide a continuous flow of fluid, making them ideal for applications that require constant fluid transfer.

- Diaphragm pump: Diaphragm pumps are known for their ability to handle abrasive or corrosive fluids. Their diaphragm mechanism ensures reliable pumping action, even in challenging fluid conditions.

- Gear pump: Gear pumps are excellent for transferring thin liquids, such as fuel or oil. They utilize interlocking gears that trap and transfer the fluid, providing a smooth and constant flow rate.

- Lobe pumps: Lobe pumps, often used in wastewater treatment applications, are designed to handle high flow rates and viscous fluids efficiently. Their lobe-like rotors generate continuous fluid flow, making them suitable for industrial applications.

- Progressive cavity pump: Progressive cavity pumps are perfect for pumping high-viscosity materials, such as slurry or paste. They utilize an eccentric rotor inside a stator to generate progressive pumping action, ensuring accurate flow rates.

Advantages of Positive Displacement Pumps

Positive displacement pumps offer several advantages over other types of pumps, making them an ideal choice for various applications. Some of the key advantages of positive displacement pumps include:

- Pump efficiency: Positive displacement pumps are highly efficient, ensuring consistent flow rates and precise fluid transfer. They maintain their efficiency even with varying viscosities, making them suitable for applications with high-viscosity fluids.

- High viscosity handling: Positive displacement pumps excel at handling high viscosity fluids, ensuring efficient operation and accurate flow rates. They can pump thick substances consistently, making them ideal for industrial processes involving viscous liquids.

- Low shear: The pumping action of positive displacement pumps involves low shear, preserving the integrity of sensitive fluids. This is especially important in applications where preserving product quality is crucial, such as in the food and beverage industry.

Efficiency and Performance

Positive displacement pumps deliver efficient performance across a wide range of operating conditions. They can generate high pressure, making them suitable for applications that require pumping against high resistance or suction lift. These pumps also perform well in low flow applications, delivering consistent fluid transfer. The efficiency of positive displacement pumps remains high even at lower speeds, ensuring precise flow control. Their ability to maintain a constant pressure and flow rate, regardless of variations, makes them reliable and efficient choices for many industries.

Handling Viscous Fluids

Positive displacement pumps are particularly well-suited for handling viscous fluids. They can efficiently pump high-viscosity fluids, ensuring a steady flow rate. This is crucial in industries where processing thick substances is essential, such as in chemical processing or wastewater treatment. Positive displacement pumps handle higher viscosity fluids with ease, maintaining a consistent flow rate and minimizing any disruptions in the pumping process. Their ability to pump viscous liquids reliably makes them an excellent choice for applications that involve transferring fluids of varying consistency.

Key Components of Positive Displacement Pumps

The essential components of positive displacement pumps facilitate efficient fluid transfer. A plunger or piston initiates the pumping action, while the rotary gear aids in fluid movement within the pump. The pump cavity is pivotal for storing and displacing the fluid effectively. Each part of these pumps contributes to fluid transfer efficiency, ensuring minimal slippage during operation. Incorporating these components results in a well-designed system capable of handling various industrial applications and fluid types with precision and reliability.

The Role of the Plunger or Piston

The plunger or piston, integral in positive displacement pumps, utilizes pressure differentials to propel the fluid through the system, ensuring a consistent flow rate. Critical for maintaining efficiency and performance, their design directly impacts the pump’s operation. These components are indispensable for creating the requisite force for effective fluid transfer by continuously displacing the fluid within the pump chamber. Their movement within the pump ensures seamless fluid displacement, contributing significantly to the overall functioning of the system.

The Function of the Rotary Gear

Within positive displacement pumps, rotary gears fulfill a pivotal role by rotating to ensnare and propel fluids through the pump system. These specialized gears are meticulously crafted to uphold a consistent volume of fluid per operational cycle, directly influencing the pump’s efficiency and performance outcomes. By executing a precise gear mechanism, these components guarantee a steadfast flow rate irrespective of fluctuations, promoting operational stability. The seamless functionality of rotary gears not only facilitates continuous fluid movement but also minimizes energy wastage within the pump apparatus.

The Importance of the Pump Cavity

Within positive displacement pumps, the pump cavity serves as the crucial space for containing and displacing fluids efficiently. The size and shape of the cavity directly impact the volume of fluid that can be effectively moved through the system. Ensuring proper maintenance of the pump cavity is essential for optimal pump performance, while the cavity design significantly influences the pump’s capacity to handle various fluid types. A well-engineered pump cavity not only facilitates efficient fluid transfer but also minimizes the likelihood of leaks, enhancing the pump’s overall functionality and reliability.

The Wide Range of Positive Displacement Pumps Applications

From chemical processing industries to oil and gas operations, positive displacement pumps find diverse applications. They are crucial in the food and beverage industry, handling viscous fluids efficiently. Whether for high flow rates or low viscosity fluids, these pumps excel due to their low shear characteristics. In wastewater treatment or delivering specific pressures, positive displacement pumps, including various types like rotary and reciprocating pumps, play a vital role. The pump speed, discharge port, and pump casing all contribute to their versatility.

Usage in Chemical Processing Industries

In chemical processing industries, positive displacement pumps are extensively utilized for precise metering and dosing of various chemicals. These pumps play a vital role in safely handling abrasive or corrosive substances within industrial settings. Offering accurate flow control, positive displacement pumps are indispensable in ensuring the efficiency of chemical manufacturing processes. Their design features are specifically crafted to prevent any contamination risks during the transfer of chemicals, guaranteeing the purity and integrity of the substances being processed. Due to their consistent and reliable performance, chemical processing industries heavily rely on positive displacement pumps for seamless operations.

Distillation

Solvent Recovery

Drying

Degassing

Molecular Distillation

Pneumatic Conveying

Importance in Oil and Gas Operations

Positive displacement pumps are crucial in the oil and gas industry, facilitating the transfer of crude oil and refined products efficiently. These pumps are instrumental in increasing pressure for oil extraction and transportation, serving both offshore drilling platforms and onshore refineries. Their robust construction and adaptability to varying pressures ensure reliable fluid movement, making them indispensable in oil and gas operations. With the ability to handle different viscosities, positive displacement pumps play a vital role in maintaining operational efficiency and consistency in the challenging environments of the oil and gas sector.

Distillation

Petroleum cracking

Oil and gas recovery

Vapor Recovery

Vacuum degassing

VOC tail gas recovery

Applications in the Food and Beverage Industry

Applications in the food and beverage industry encompass a wide array of uses for positive displacement pumps. These pumps play a crucial role in transferring various liquids such as fruit juice and dairy products within production processes. They are particularly essential when handling sensitive fluids that require precise and gentle transfer methods. In this industry, positive displacement pumps are commonly utilized for pumping liquid ingredients like syrups and sauces efficiently. Moreover, they are suitable for managing high-viscosity substances like chocolate and honey, as well as for transferring thick liquids such as tomato paste and cream.

Vacuum Cooling

Freeze drying

Vacuum packaging

Pneumatic conveying

How to Choose the Right Positive Displacement Pump

When choosing the right positive displacement pump, factors like the type of fluid being pumped, flow rate requirements, necessary pressure levels, temperature conditions, and specific viscosity analysis are crucial. Understanding these aspects ensures optimal pump selection for industrial applications. Different types of positive displacement pumps such as rotary pumps cater to specific needs like handling high viscosity fluids in wastewater treatment or low viscosity fluids in sensitive liquid applications. Evaluating the pump efficiency based on the centrifugal pump curve and considering the discharge valve for constant flow are essential. By assessing particular pressure requirements and the volume of fluid to be transferred, the right pump design, whether diaphragm, gear, or lobe pumps, can be chosen to meet diverse operational demands effectively.

Considering the Fluid Properties

When choosing a pump, it’s crucial to consider the viscosity of the fluid to ensure seamless operation. Additionally, the pump should be capable of handling any abrasive components present in the liquid without causing damage. Temperature compatibility is another key factor to keep in mind when selecting a pump to maintain optimal performance. Efficiency is enhanced when the pump’s flow rate matches the requirements of the application. Lastly, choosing a pump design that aligns with the sensitivity of the fluid being pumped is essential for smooth and effective operation.

Assessing the Operational Requirements

When assessing operational requirements for positive displacement pumps, it’s crucial to determine the needed pressure levels and evaluate the required flow rates. Additionally, considering ambient temperature conditions, available space for installation, and power source requirements are vital for optimal pump performance. By assessing these factors thoroughly, one can ensure the efficient operation of the pump system across various industrial applications. Incorporating types of positive displacement pumps, pump efficiency, high viscosity fluids, and other NLP terms enhances the understanding of the operational demands for these pumps in different settings.

Are Positive Displacement Pumps the Right Choice for Your Application?

Positive displacement pumps are a reliable choice for applications that demand consistent flow rates, efficient handling of viscous or fragile fluids, and effective operation even with suction lift requirements. These pumps are particularly well-suited for scenarios where low flow rates and high pressures are essential. In addition to these advantages, positive displacement pumps offer precise control over flow rates, making them a preferred option in various industries such as oil and gas, food processing, and pharmaceuticals.

When it comes to vacuum pump applications, seeking expert advice is crucial to ensure optimal performance and efficiency. Our team of specialists is equipped to provide guidance on selecting the right vacuum pump for your specific needs. Whether you require assistance with maintenance, troubleshooting, or optimizing your vacuum pump system, our experts are here to help you achieve seamless operations and maximum productivity.

Due to the simple structure of the working principle of the Roots blower, long service life, so the maintenance cost of the Roots blower is relatively low, while the screw blower due to the complex structure, the need for regular inspection and maintenance, maintenance costs are relatively high maintenance.

Conclusion

Positive displacement pumps offer precise fluid control and versatility across various industries. Their ability to handle viscous fluids efficiently makes them indispensable in chemical processing, oil and gas operations, and the food and beverage sector. Understanding the pump components and operational requirements is crucial when choosing the right pump for your application. If you seek reliable and accurate fluid transfer solutions, positive displacement pumps are a top choice. Contact us for quotes and explore how these pumps can enhance your industrial processes.