Knowledge

Analysis of the Application of Vacuum Technology in the Field of Degradable Plastics

On April 2, the first reactor of 50,000 tons/year polyglycolic acid (PGA) demonstration project of National Energy Group Yulin Chemical Co., Ltd. was lifted and completed, laying the foundation for the completion and operation of the pre-polymerization unit.

The 50,000 tons/year PGA demonstration project is located in Qingshui Industrial Park, Dabaodang Town, Shenmu City, Yulin City, Shaanxi Province, covering an area of 9.8 hectares, and is the world’s first polyglycolic acid plant with a total investment of about 1 billion yuan. After the project is put into operation, it will achieve a zero breakthrough in the field of degradable plastics (PGA) in China.

Understanding Polyglycolic Acid (PGA)

Polyglycolic acid (PGA), also known as polyhydroxyacetic acid, is an aliphatic polyester polymer with the lowest unit carbon number, a completely decomposable ester structure, and the fastest degradation rate.PGA is also a thermoplastic aliphatic polyester with a glass transition temperature of 40°C and a melting temperature of approximately 225°C.

Characteristics and applications of PGA

1.Whole degradability and good biocompatibility

PGA is a fully biodegradable material, its degradation conditions are mild, under the action of water and microorganisms, it can achieve rapid degradation in the natural environment, and the final degradation products are carbon dioxide and water. In addition, PGA can also be degraded in seawater, and its degradation products are harmless to human body and environment.

Because PGA has good biocompatibility, it can be degraded to water and carbon dioxide in human body, so it is widely used in medical surgical sutures, internal fixation of fracture, tissue engineering repair materials and drug control release system, etc. It is an important branch of current biomedical polymers.

PGA surgical suture

2.High mechanical strength

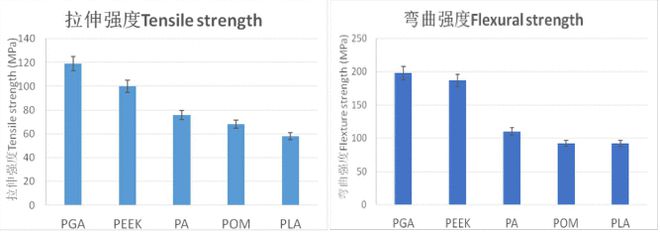

PGA has high mechanical strength, its mechanical properties are better than common general-purpose plastics and other degradable plastics, and comparable with engineering plastics.PGA has high crystallinity (45%~55%), its mechanical properties are close to ABS and other engineering plastics, better than some other degradable plastics. It can be used for extrusion and injection molding with a variety of other polymer materials, and can be blended with other resins to prepare polymer alloy materials, and its excellent mechanical properties can help reduce weight.

3.High barrier property

PGA material has very good vapor/oxygen barrier performance and is one of the best comprehensive barrier materials. Its barrier performance to water vapor is 100 times higher than that of PLA, which is similar to PE material. In view of its excellent barrier performance, PGA can be widely used in fresh packaging, bottle materials and other fields.

PGA production process and vacuum

The traditional ethanoic acid production process is mainly through the condensation of ethanoic acid, ethanoic acid ester, ethyl cross ester and other raw materials under the action of catalyst, the process technology route to ethyl cross ester ring opening polymerization method, but this method is toxic, high cost, not conducive to large-scale production.

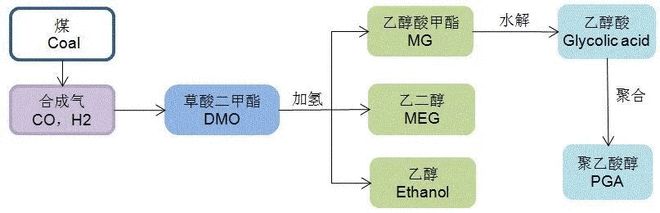

With the development of coal to ethylene glycol industry, the large-scale production of PGA from dimethyl oxalate (DMO) has become a feasible process route. There are two main process routes for the hydrogenation of dimethyl oxalate (DMO) to methyl glycolate (MG) and then the production of polyglycolic acid (PGA) from methyl glycolate (MG).

- Methyl glycolate (MG) is synthesized by direct condensation of PGA by heating and de-alcoholization under the action of catalyst.

- Hydrolysis of methyl glycolate (MG) to ethanoic acid, ethanoic acid to the intermediate product ethyl cross ester, ethyl cross ester ring opening polymerization to PGA.

It is worth noting that both DMO to PGA processes need to be carried out under vacuum when the polymerization reaction occurs, otherwise the high molecular weight PGA polymer and the ethyl cross ester will not be produced. The vacuum reactor and vacuum acquisition equipment are indispensable.(The vacuum reactor is an important reaction equipment for the pre-polymerization unit of the project

The second vacuum reactor weighing 46 tons is being lifted

The vacuum equipment of this project is designed and manufactured by Vacculex Vacuum Equipment (Zhejiang) Co.Ltd, The company provided a total of 14 sets of vacuum equipment for the project. Among them, 4 sets of VSP series dry screw vacuum units and 2 sets of MBVSP series Roots screw compound vacuum units are used for the product tower, 2 sets of MBVSP series Roots screw compound vacuum units are used for the thickening tower, and 6 sets of MBVLRC series Roots liquid ring compound vacuum units are used for the de-volatilization device. The vacuum solution, with advantages of large pumping speed, large compression ratio and low noise, provides strong technical support for the efficient production of the project.